Comprehensive manufacturing solutions, from conceptual design to full-scale production

Xianfeng's commitment to you:

*Strict process standards:

Xianfeng has a strict set of process standards for SLS nylon printing to ensure the quality and consistency of all printed parts.

*Competitive prices:

Whether nationwide or globally, our prices are extremely competitive

*The shortest delivery time is 2 days:

The standard process of industrial production ensures the timeliness of printing, which can be completed within 2 days at the shortest

Why choose SLS?

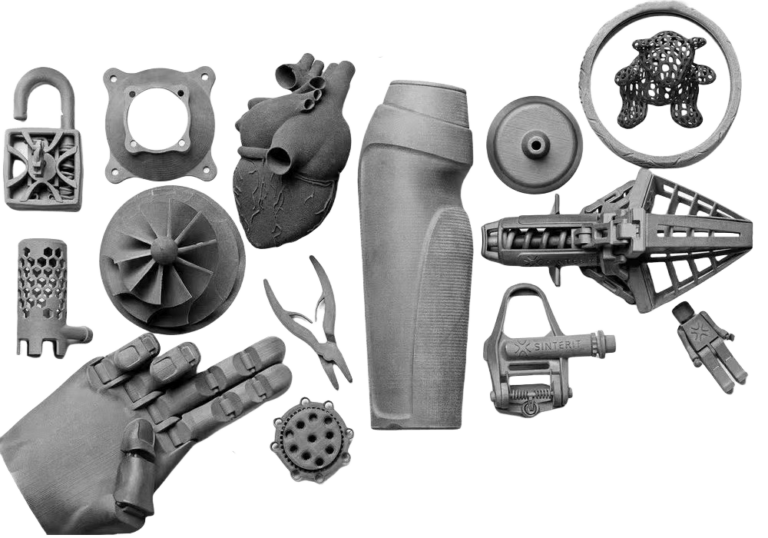

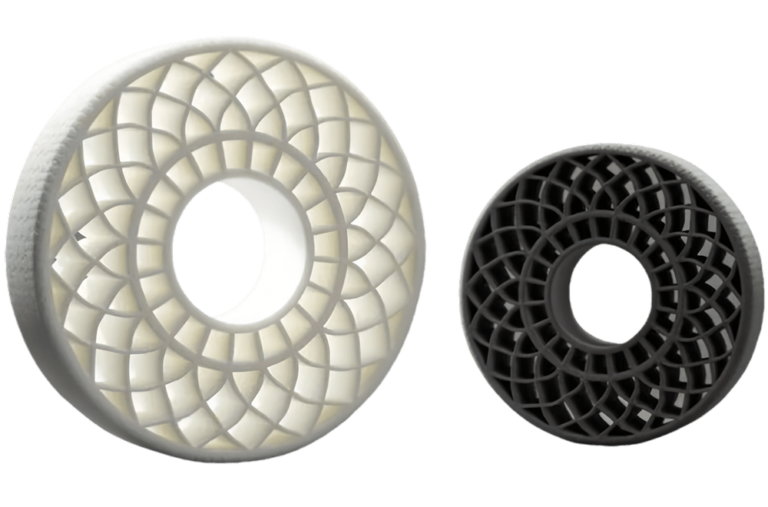

Compared with other additive manufacturing methods, selective laser sintering (SLS) technology has unique advantages. Compared to stereolithography SLA or fused deposition FDM technology, SLS does not require additional support structures, meaning that complex geometric shapes can be constructed without the need for additional removal of support steps. The adhesive strength between layers in SLS 3D printing is excellent, which means that the parts printed by SLS have almost isotropic high-strength mechanical properties. And unsintered powder materials can be mixed and recycled in a ratio of 2:8 to achieve sustainable development. In fact, SLS technology has become a powerful and versatile choice.

*Can produce complex functional components such as lattice structures.

*Prototype manufacturing, rapid response to design end

*Small batch production is cost-effective

*Save time and cost from design to entity conversion, and shorten the research and development cycle.

On demand manufacturing

SLS 3D printing is highly suitable for functional prototyping and small to medium batch production of end use components. Choosing SLS3D printing for producing 1-10000 units of parts is definitely more cost-effective.

3D printing cost

10 days

Unit Price

Delivery time

Total cost

10000 parts using molds

three months

Xianfeng focuses on industrial 3D printing polymer material technology, which enables us to ensure consistent high product quality and process stability. In the field of SLS technology, we have independently developed various polymer powder materials based on customer needs, covering many industrial applications. For our customers, this means reliable quality, repeatability and reliability, short delivery times, and competitive prices.

If you want to improve the strength, clarity, or appearance of 3D printed parts? Xianfeng offers a variety of post-processing techniques to choose from.

Ordering process

Contact Us

Understand your requirements, evaluate the volume and industry value of your needs, and preliminarily determine whether SLS technology can be adopted based on appearance, wall thickness, and performance.

Send STL file

Our process engineers will handle drawings: check the external dimensions, wall thickness, fit, roughness, dimensional accuracy, deformation, thermodynamic properties, acid and alkali resistance, and other usage requirements to ensure they are met.

Confirm part specifications and delivery time

We will provide specific delivery times based on the customer's product size and selected materials. The normal delivery time for SLS 3D printing is one week, and the fastest delivery time is only three days.

Offer

Provide a quotation based on your printing quantity and materials.

Production

Experienced process engineers will ensure the best quality of printed parts at every stage of production.

Delivery

Check the production quality inspection form, inspect the quantity, quality, size, deformation, fit, etc. to ensure there are no errors before shipping.

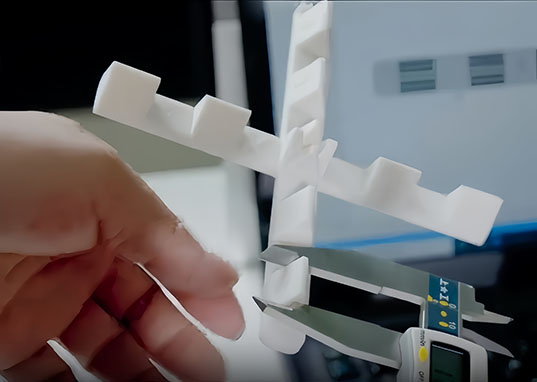

Quality Control

Highly specialized

If the requirements for small-scale production can be achieved, then consistency and performance stability must be another step forward. From printing technology to material formulation, the Xianfeng team is highly professional, accurately controlling precision and surface quality, and producing consistently high-quality 3D printed plastic parts.

Product Factory Inspection (Testing) Specification

As an experienced 3D printing service provider, we always focus on printing results.

We inspect according to strict manufacturing standards, including appearance, printing features, orange peel, cracks, warping, scratches, hole and surface fit, dimensional accuracy, splicing, and other feasible technical requirements required by customers.