Polymer powder materials

All material launches are based on market demand and validation, and with 15 years of experience in 3D printing services, we have a deep understanding of customer needs.

Any 3D printing starts with an application, and then the application selects the material

With the maturity and rapid development of SLS technology, continuously developing materials with different properties to meet the application needs of more customers is currently the most important thing. Accurately grasping the formula of materials and accumulating experience in process research are our unique advantages. Compared to other polymer 3D printing processes, SLS technology is more complex and requires a thorough understanding of materials, processes, and technical equipment to complete production. This not only requires professionalism, but also practical accumulation. Pre wind polymer materials undergo rigorous testing to ensure they meet the highest performance and reliability standards.

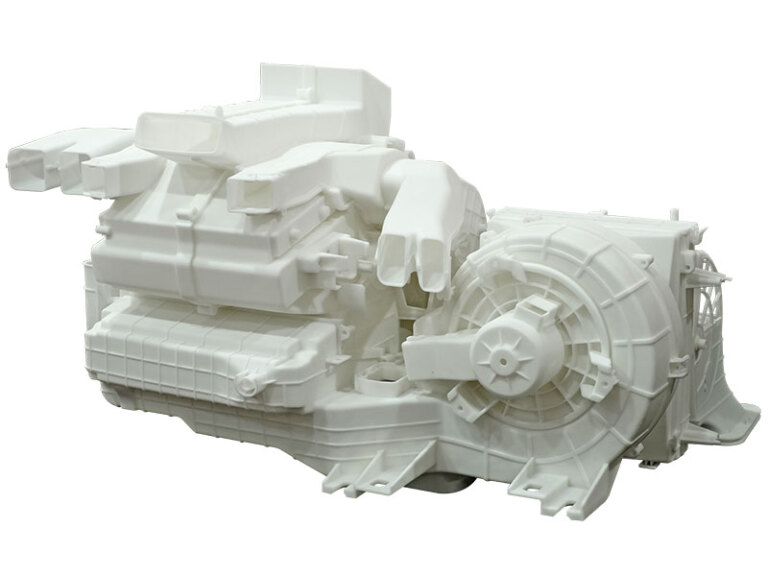

There are various types of 3D printing materials for Xianfeng Plastic, each with its unique properties and advantages. Searching for suitable materials for your manufacturing project.

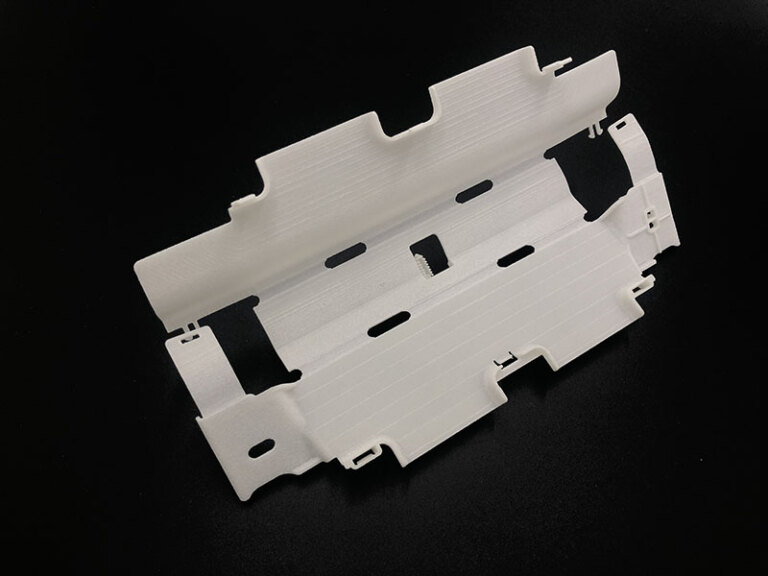

XF1200PA

Color: White

Material characteristics:

- Good resilience

- Corrosion resistance

- Good surface quality

- Stable molding process

- Good dimensional stability

Application:

Suitable for functional component verification, small-scale production, especially for applications in prototype, automotive, aerospace, medical, and household appliances.

XF1200F

Color: Black

Material characteristics:

Good resilience

Corrosion resistance

Good surface quality

Stable molding process

Good dimensional stability

Application:

Suitable for functional component verification, small-scale production, especially for applications in prototype, automotive, aerospace, medical, and household appliances.

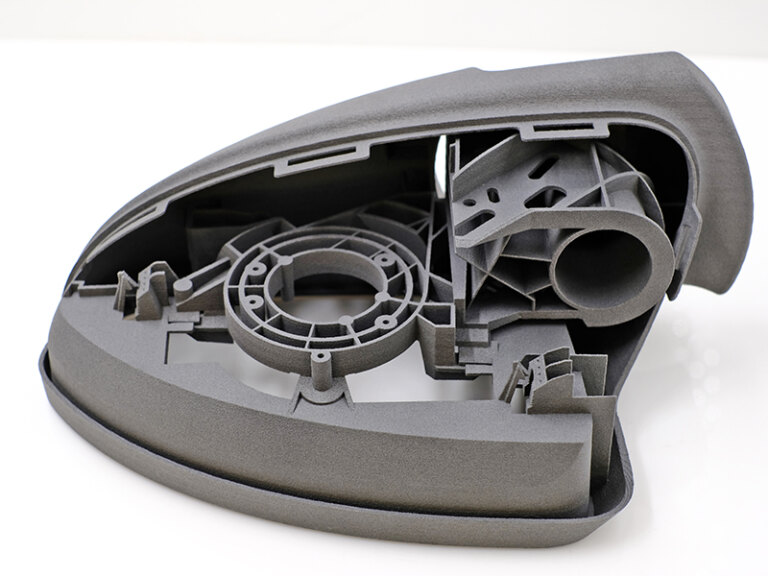

XF1200GF

Color: Light Grey

Material characteristics:

This material has excellent characteristics such as good rigidity, good heat resistance, stable molding process, and good dimensional stability.

Application:

Suitable for functional component validation, small-scale production, replacing CNC and injection molded parts, especially suitable for applications such as prototype, automotive, and power tool casings.

XF1100PA

Color: White

Material characteristics:

Excellent toughness, heat resistance, corrosion resistance, biocompatibility, and low temperature resistance.

Application:

Very suitable for applications such as automotive and medical.

XF7100CF

Color: Black

Material characteristics:

XF7100CF nylon composite material has excellent chemical resistance, oil resistance, and temperature resistance, good toughness, and high strength, and can be used as a functional component.

Application:

Suitable for military industry.

XF 3100PG

Color: Black

Material characteristics:

It has the characteristics of light weight, good toughness, and good chemical resistance.

Application:

Suitable for applications such as automotive interior and exterior, medical, clothing, helmet lining, etc.

XF2100PX

Color: White

Material characteristics:

It has the characteristics of high elasticity, high impact resistance, and fatigue resistance.

Application:

Suitable for applications such as shoe midsoles, automotive interior and exterior, medical, clothing, helmet linings, etc

The demands of customers are diverse, and the continuous development of materials and processes with different properties has always been the focus of Xianfeng,

If these materials still cannot meet your needs, please let us know and we will open the door to applications together.