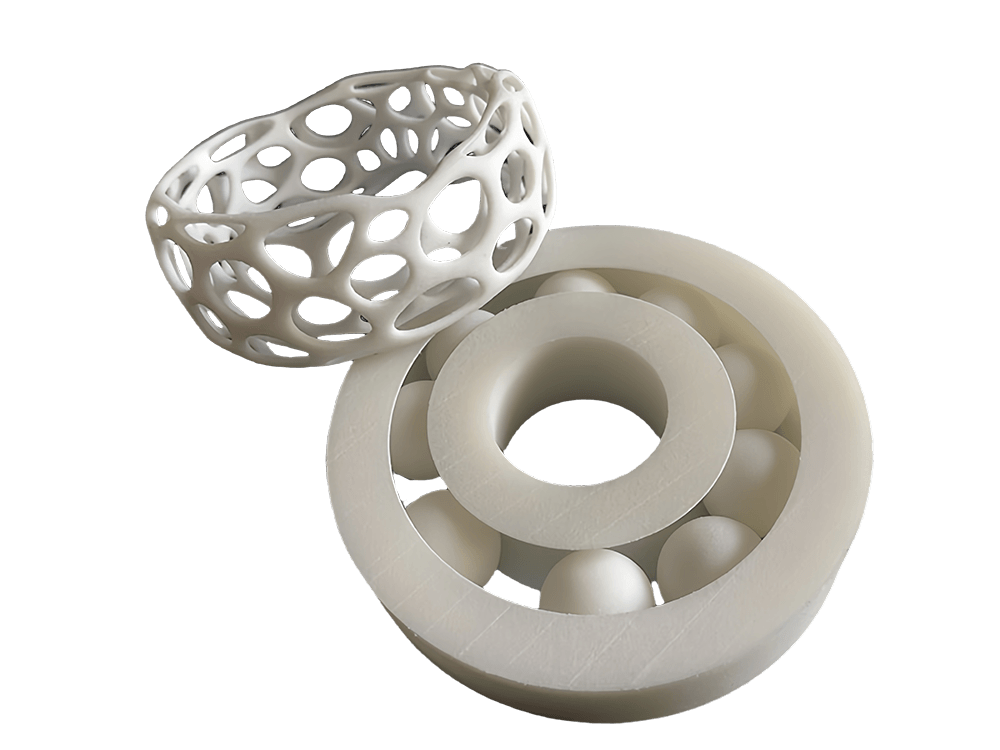

The parts produced by the manufacturing process of SLS3D printing can be used directly. Their natural surface has a sandy granular appearance, which feels slightly rough to the touch. However, the surface smoothness of products manufactured by this process may not be ideal for certain applications. Therefore, suitable post-processing techniques can be selected according to customer needs to enhance the appearance and functionality of 3D printed polymer components.

Machine polishing to remove small burrs on the surface and reduce the surface roughness of the product.

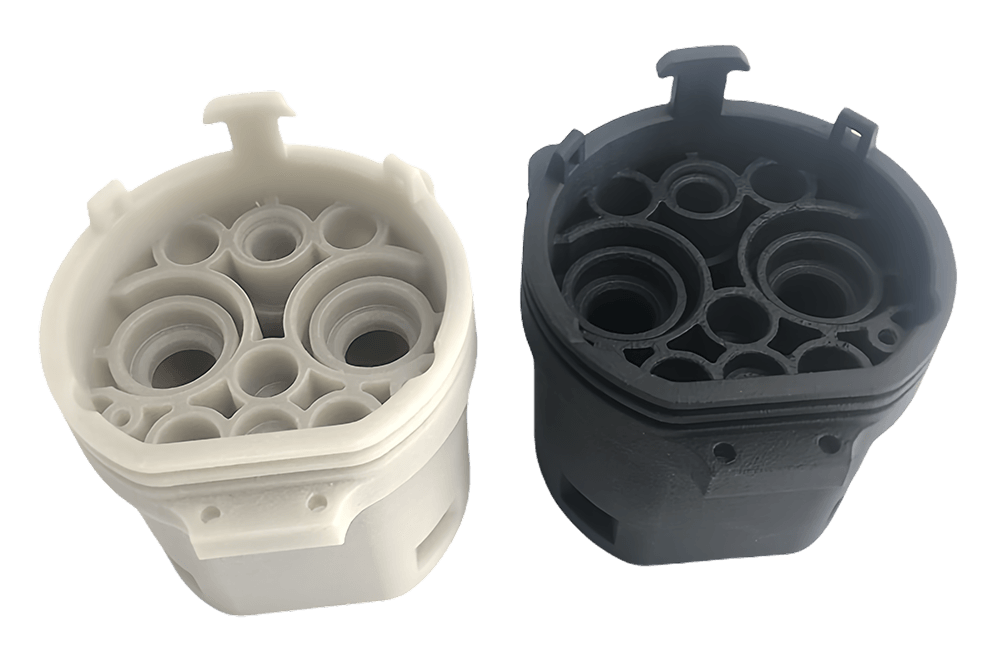

Ensure that the high standard dimensional accuracy of the product meets the design requirements and can be used for assembly between components.

Enhance product surface recognition and improve product toughness

Improve product surface smoothness, water tightness, air tightness, and oxidation resistance.

Improve the mechanical performance, air tightness, and water tightness of the product, reduce the surface roughness of the product, and make the color brighter.

Enhance the surface smoothness, water tightness, air tightness, and oxidation resistance of the product, effectively improve its appearance and decorative properties, and also improve its performance in electrical, thermal, and corrosion resistance aspects.

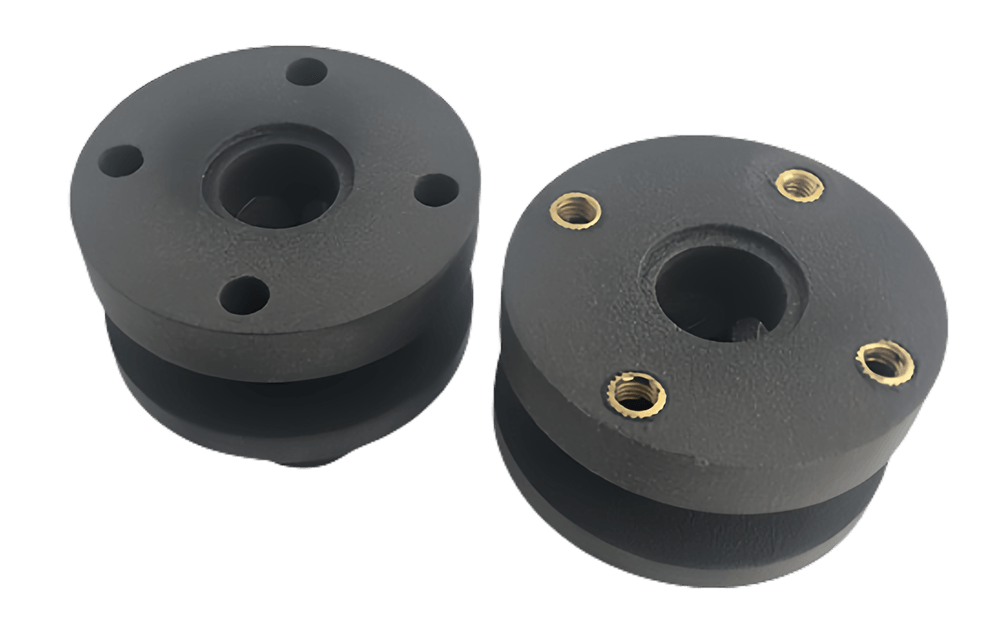

Improve the feasibility and tightness of product resistance to repeated assembly.

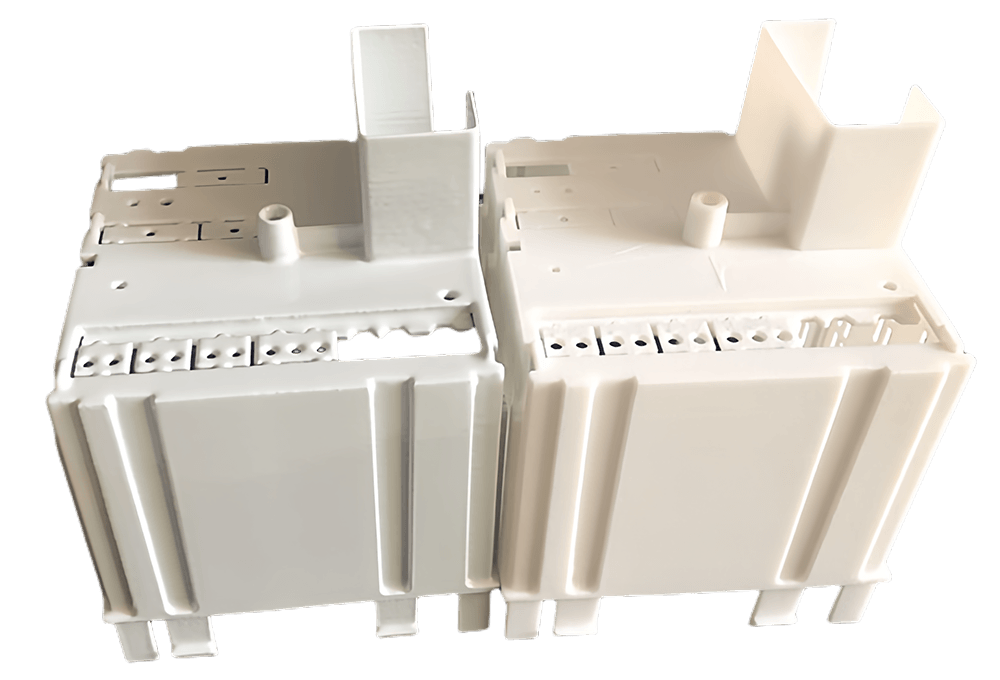

Improve the limitations of product printable size.

Changzhou Xianfeng 3D Technology Co., Ltd. is a leading company in the polymer powder 3D printing service industry, known for manufacturing high-quality parts at competitive prices. Since its establishment, the company has adhered to the principles of “sincere service, high-quality products, reasonable prices, and honest management”, established long-term friendly partnerships with customers, and won their recognition and support!

Copyright © 2024 Changzhou Xianfeng 3D Technology Co., Ltd. All rights reserved.