Medical industry

Provide personalized customized medical 3D printing solutions

Polymer 3D printing provides countless benefits that can meet the constantly changing needs of the healthcare industry, with one of the most important benefits being customization. With the ability to create patient specific implants and restorations, additive manufacturing is fundamentally changing the way healthcare is delivered. In addition, the biocompatibility of many materials ensures that the body can absorb printed parts without complications.

However, addressing the challenges customers face in terms of reliable production and regulatory compliance is crucial, and polymer 3D printing can precisely meet this demand. It ensures excellent dimensional accuracy and repeatability, ensuring consistency and reliability in the production of important medical components. Compliance with strict regulations is simplified as this technology allows for the creation of components that meet industry standards, ultimately improving patient safety and quality of care.

The advantages of 3D printing

Personalized customization

We use high-performance materials to enhance the possibility of customized product features.

- By utilizing advanced materials and designs, 3D printed prostheses are more lightweight, breathable, and functional, enhancing the patient's experience

- Allow customization based on each patient's specific situation to ensure the fit and comfort of the prosthetic.

Lower production cost

We offer SLS 3D printing services aimed at overcoming complex geometric shapes and producing lightweight components.

- On demand production

- Lower production cost

- SLS 3D Printing Helps with Low Cost, Small Batch Production

Short cycle

Accelerate prototype manufacturing and product development for producing parts

- The 3D printing service provided by Xianfeng can shorten the production time of prosthetics from weeks to days, greatly improving production efficiency.

- We have achieved integrated molding without the need for assembly, greatly reducing production steps and improving overall production efficiency.

Xianfeng's Manufacturing Capability in Personalized Customized Medical Industry

- Instrument casing

- Surgical guide plate

- Waist and leg rehabilitation

- Protective gear

- Correct insole

- Scoliosis brace

- Customized helmet

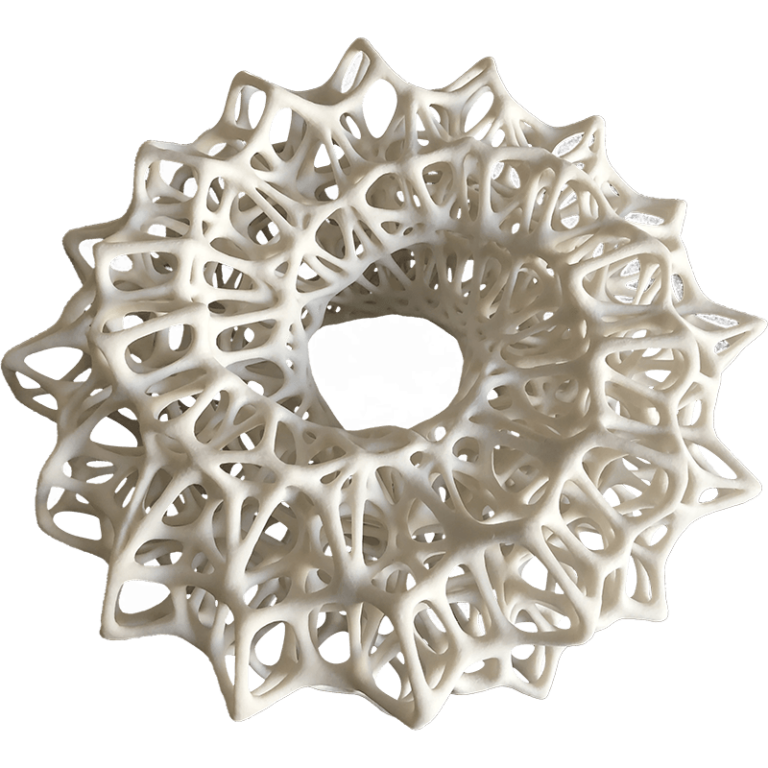

Case Presentation

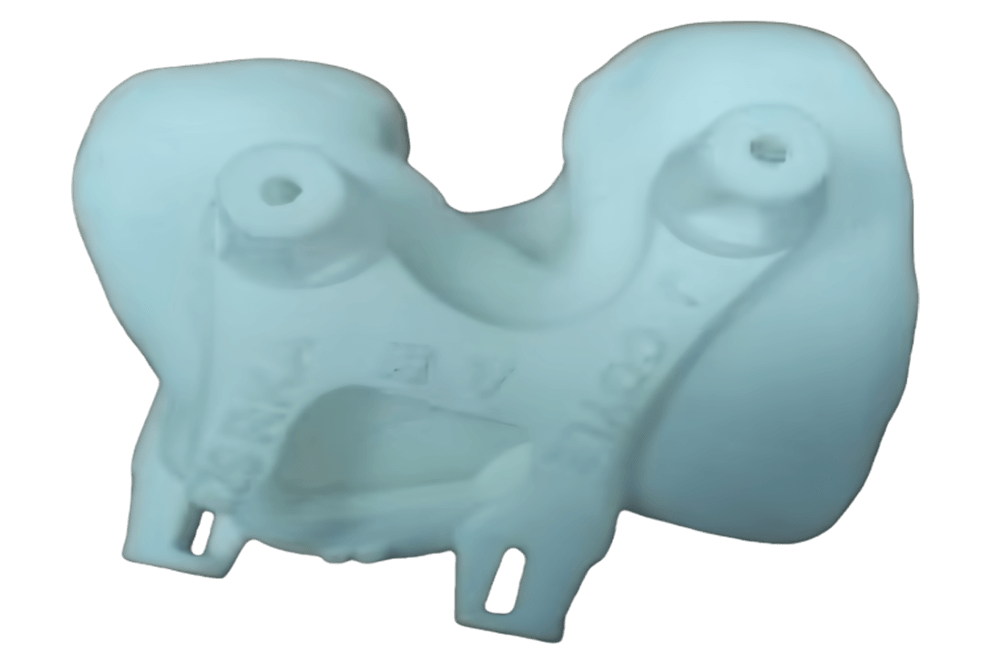

Surgical guide plate

Requirement: The surgical guide plate is customized and designed based on the patient’s lesion data, with high precision requirements. During surgery, it is attached to the joint surface for positioning and guides the doctor to the corresponding precise position.

Solution: Design guide plate shapes based on patient differences, and 3D print high-precision restoration of design data.

Result: The use of this guide plate reduces the risk of unnecessary or erroneous incisions, resulting in less surgical trauma. Shortened the surgical steps and reduced the patient’s time during surgery. It greatly reduces the pain of patients.

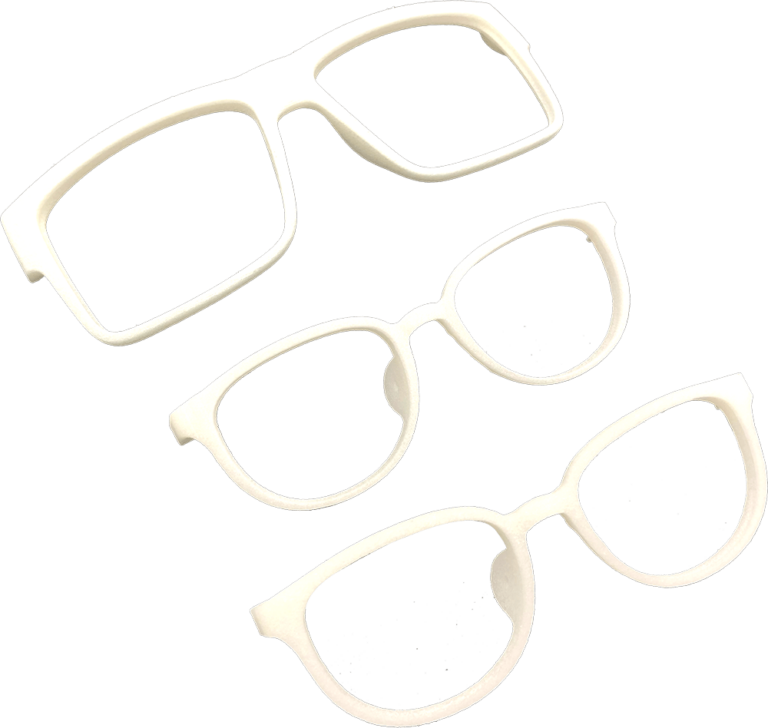

Personalized insoles

Requirement: As personalized insoles are designed based on individual foot characteristics, traditional methods cannot meet the requirements within a few days. 3D printing can effectively solve this problem.

Solution: Firstly, a 3D scanner scans the plantar information to generate a foot model. Then choose a material that meets the requirements of strength, toughness, and production time.

Result: The performance of 1200F material parts is more suitable for the feet, anti slip, and does not make people feel that the insole is too hard or too soft, making it more comfortable to wear.

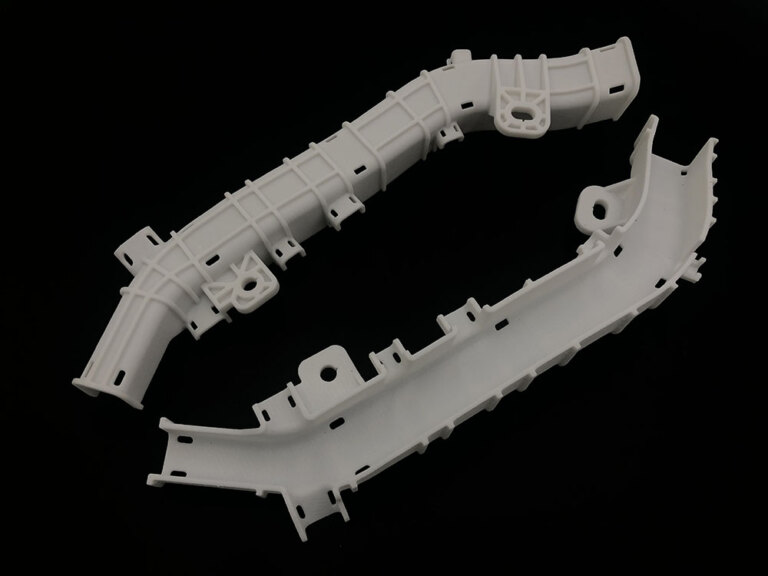

Waist protection

Requirement: Patients need to repeatedly load and unload the protective gear during months of use, and the material of the protective gear must have high strength and ultra-high toughness.

Solution: 3D printed orthotics have higher precision, better adhesion, lighter weight, better breathability, reduced volume while maintaining high durability. Compared to nylon 12 material, 1100PA has higher toughness and strength, and better biocompatibility.

Result: Enable patients to better adapt to treatment and ensure successful orthopedic procedures.