Aerospace and Military Industry

Rapid prototyping and small-scale production of lightweight and durable components

Polymer additive manufacturing meets the specific requirements of the industry for hazard levels and materials, and its weight is about half that of most traditional solutions. This allows airlines and manufacturers to significantly reduce their parts storage and even switch to just in time production, no matter how complex the part design may be.

The tool free process allows for simplified operations at lower costs and helps airlines reduce their carbon footprint by lowering transportation costs and reducing part weight.

The advantages of 3D printing

High performance

We use high-performance materials to enhance the possibility of customized product features.

- High performance plastics are most commonly used for manufacturing end functional components

- Replacing metal components with sturdy high-performance plastic parts can significantly reduce the weight of aircraft, spacecraft, and satellites, thereby improving fuel and size efficiency.

- High performance plastics can be comparable to metals

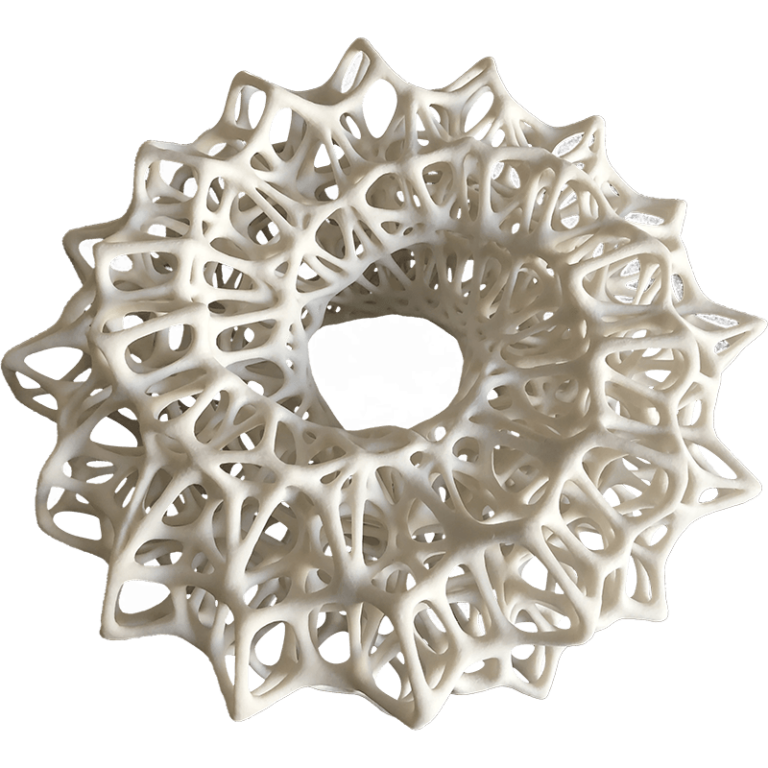

Can achieve complex structures such as hollowing out

We offer SLS 3D printing services aimed at overcoming complex geometric shapes and producing lightweight components.

- Lightweight structure

- Hollow structure

- Integrated structure implementation

- Design innovation

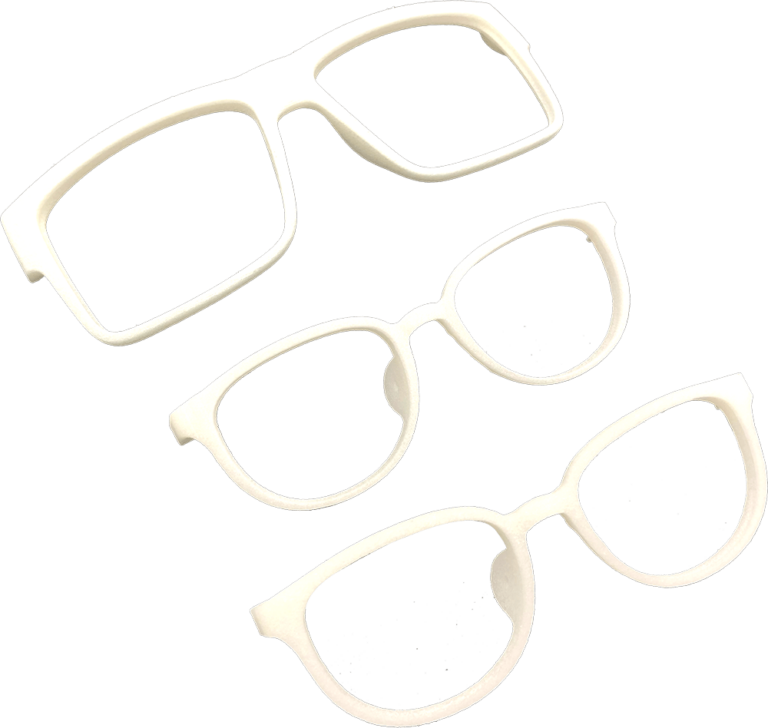

Short cycle

Accelerate prototype manufacturing and product development for producing parts

- On demand production

- Lower production cost

- SLS 3D Printing Helps with Low Cost, Small Batch Production

- Can quickly complete the process from prototype design to production manufacturing, reducing costs by 70%

Xianfeng's Manufacturing Capability in Aerospace and Military Industry

- Shaft sleeve connector

- High pressure gasket

- impeller

- Door handle

- Joystick

- Antenna cover

Case Presentation

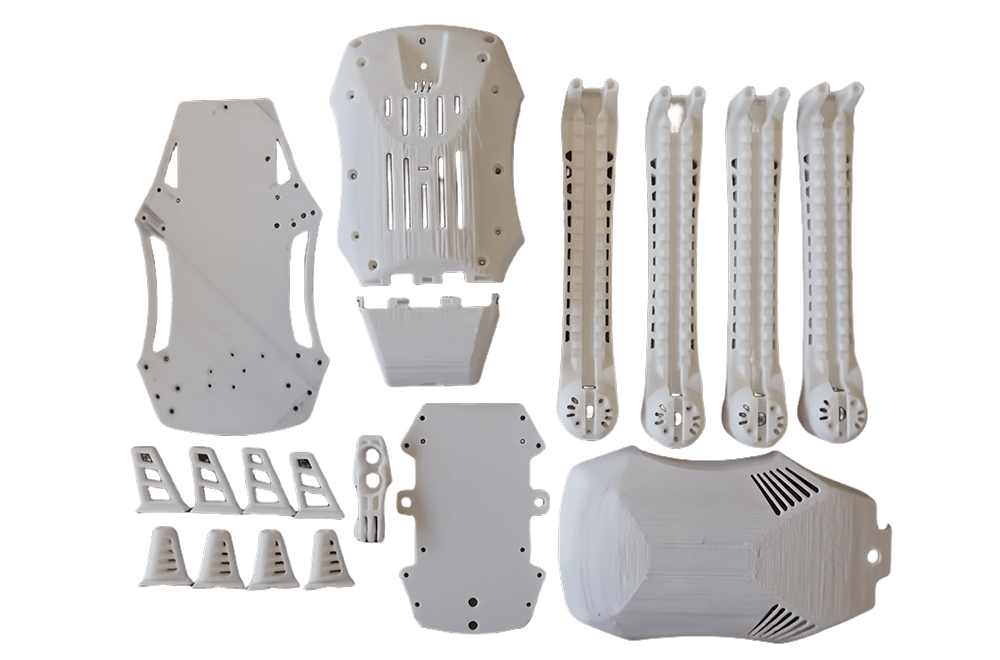

UAV

Requirement: The prototype is heavy and affects the performance of the drone. Lightweight materials with certain strength and toughness should be selected to achieve the goal of reducing the weight of the body.

Solution: Lightweight design reduces self weight, streamlined body design reduces wind resistance, PA 12’s high tensile strength and impact resistance provide lightweight and durable components that can withstand strict operational requirements

Result: Integrated molding, shortening production cycle. No need to mold, small batch directly

Assemble and use.

Fuel filling port

Requirement: Installed on the upper part of the aircraft fuel tank, used for refueling fuel into the tank, and the anti ignition internal ventilation pipeline is used to avoid fuel failure during refueling. Due to exposure during flight, it is required that the item has high toughness and does not crack at minus 40 ℃.

Plan: According to the experiment, the nylon 12 component barely meets the requirements at minus 40 ℃, so for safety reasons, nylon 11 material, which currently has better low-temperature resistance, is selected.

Result: Meeting the requirements for trial assembly and testing, the first batch has been delivered.

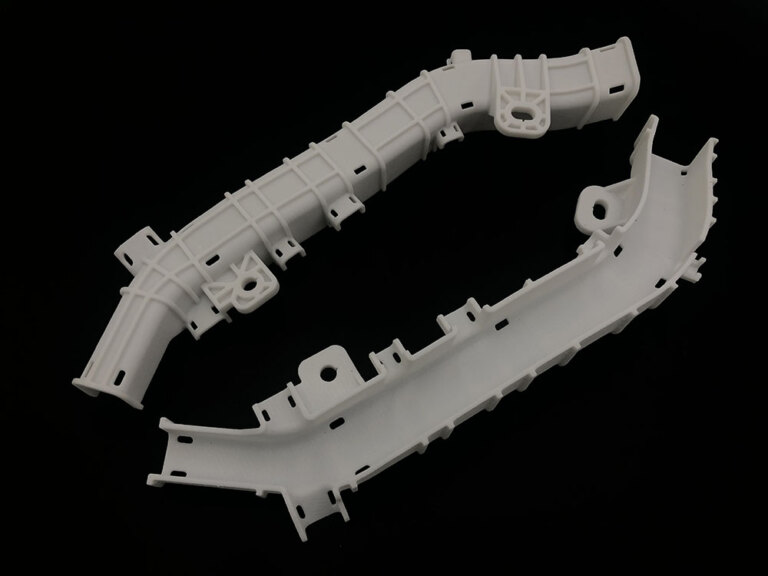

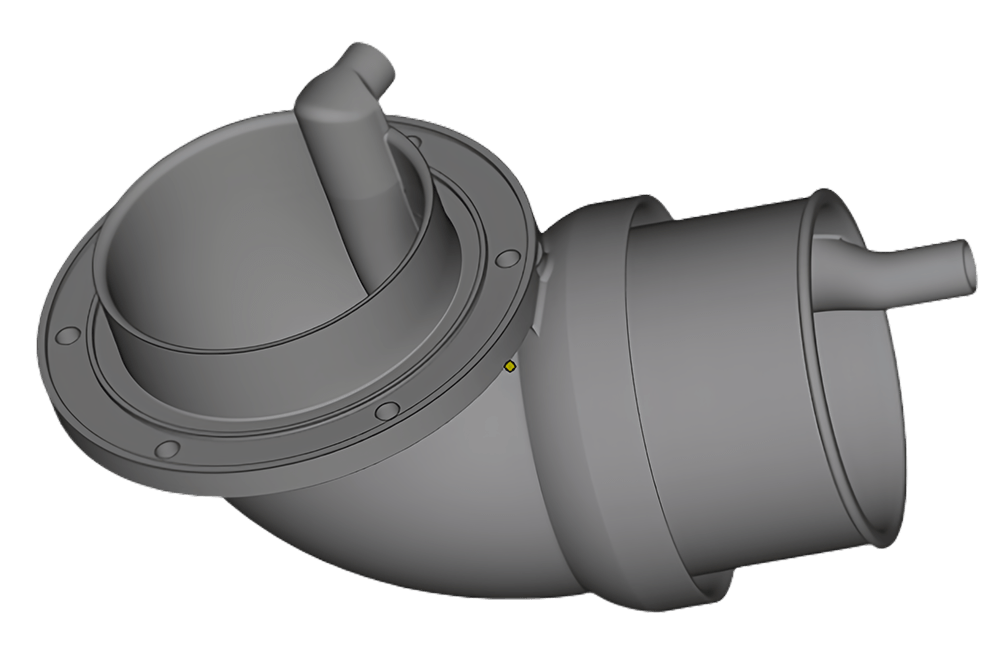

Air transport pipeline

Requirement: For the aerospace industry, the lighter the weight, the higher the payload of the aircraft, and fuel consumption and safety will also be affected.

Solution: Adopting a lightweight and perfectly matched geometric shape of the cabin wall through 3D printing, in order to achieve the goal of reducing weight for the aircraft.

Result: While meeting design requirements, it also enables designers to visualize in a visual way

Quickly and economically modifying 3D models greatly reduces time costs.