Automobile motorcycle accessories

Realize the production of lightweight and customizable automotive parts

3D printing technology plays a very important role in the automotive industry, as it can greatly shorten the development cycle of automobiles and save production costs, freeing traditional automobile manufacturing from dependence on molds. These advantages have made the application of 3D printing technology increasingly widespread in the automotive manufacturing industry.

The advantages of 3D printing

Shorten the automotive research and development cycle

Accelerate prototype manufacturing and product development for producing automotive parts

- On demand production

- Lower production cost

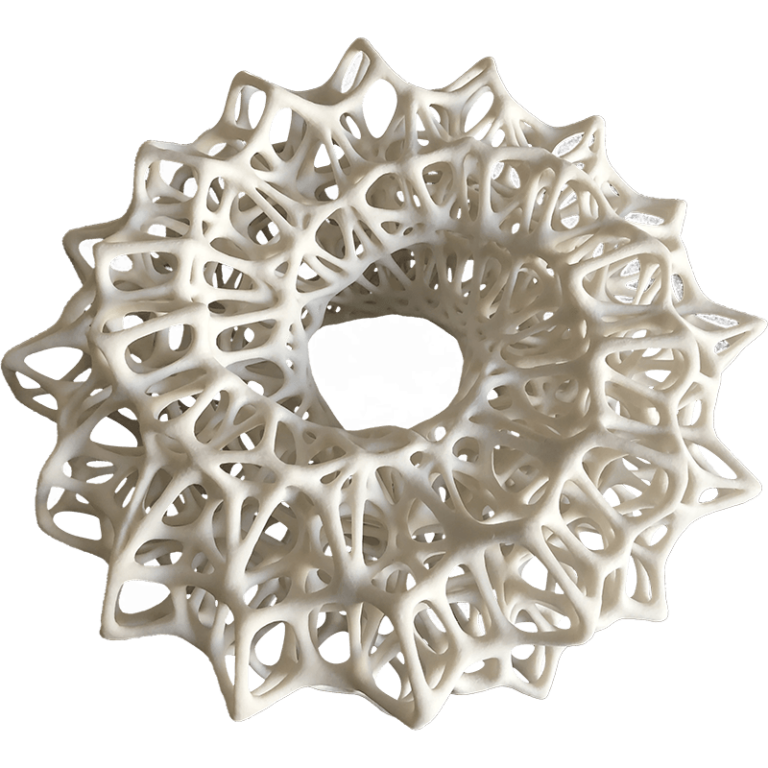

Complex structure

We offer SLS 3D printing services aimed at overcoming complex geometric shapes and producing lightweight components.

- Lightweight structure

- Hollow structure

- Integrated structure implementation

Quality assurance

Each component undergoes rigorous material testing to ensure the highest standards of performance and compliance.

- Consistency testing

- Quality inspection

- Surface inspection

Xianfeng's Manufacturing Capability in the Automotive Industry

- Car lamp housing

- Dashboard

- Mudguard

- accelerator pedal

- Air intake grille

- Bumper

- air filter housing

- Engine water tank cover

- Engine fan blades

- Pedal

- Steering column cover

- Tail light cover

- External decoration

- Battery module

- Fan cover

- Steering column cover

- Tail light cover

- Wheel trim

- Radiator blades

- Fan blades

- Intake manifold

- Intake duct

- Vacuum connection tube

- Electrical instrument casing

- Pump impeller

- Interior trim

- Hose

- The gear lever

- Chair

Case Presentation

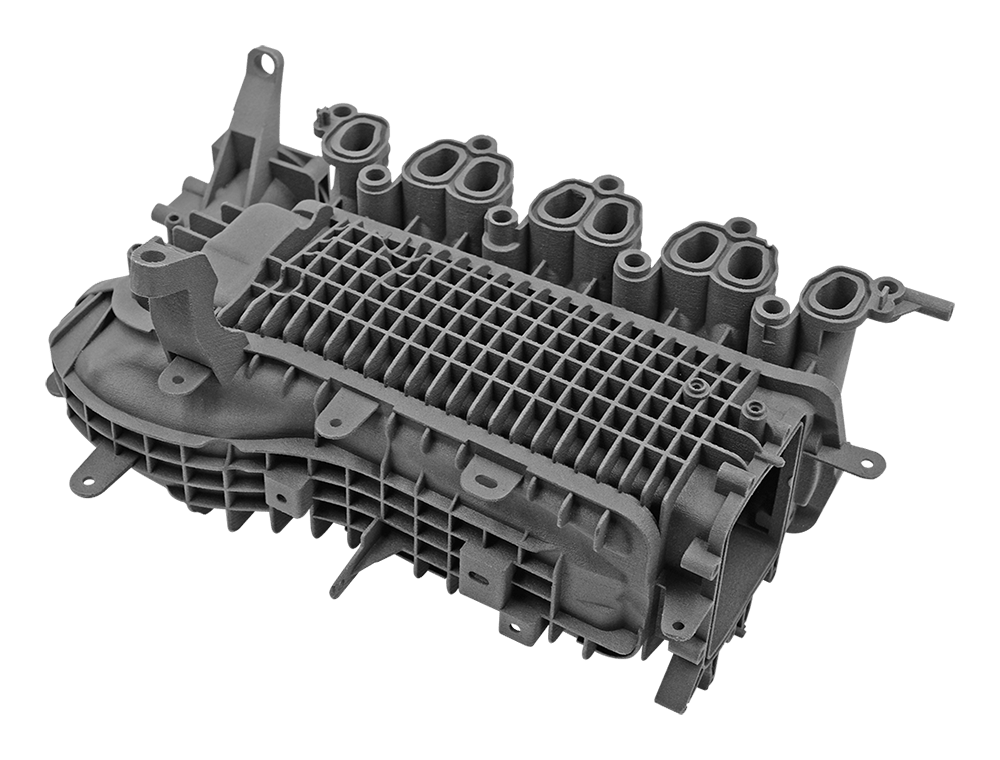

Automotive intake manifold

Nylon 6 composite fiberglass material with a melting point of up to 223 ℃. Its ultra-high strength can withstand higher loads. And it can maintain excellent mechanical properties and creep resistance at high temperatures, and can be directly used in the production of end products.

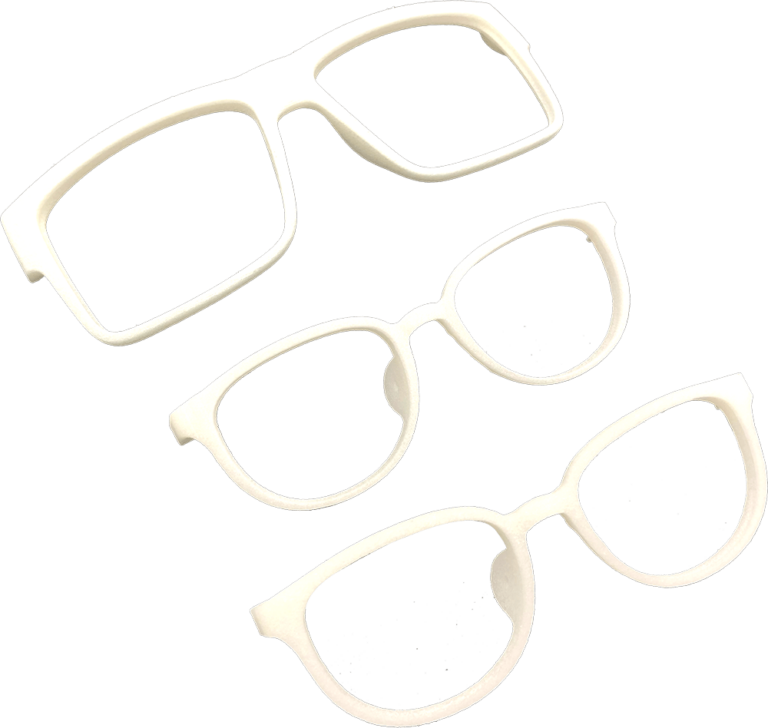

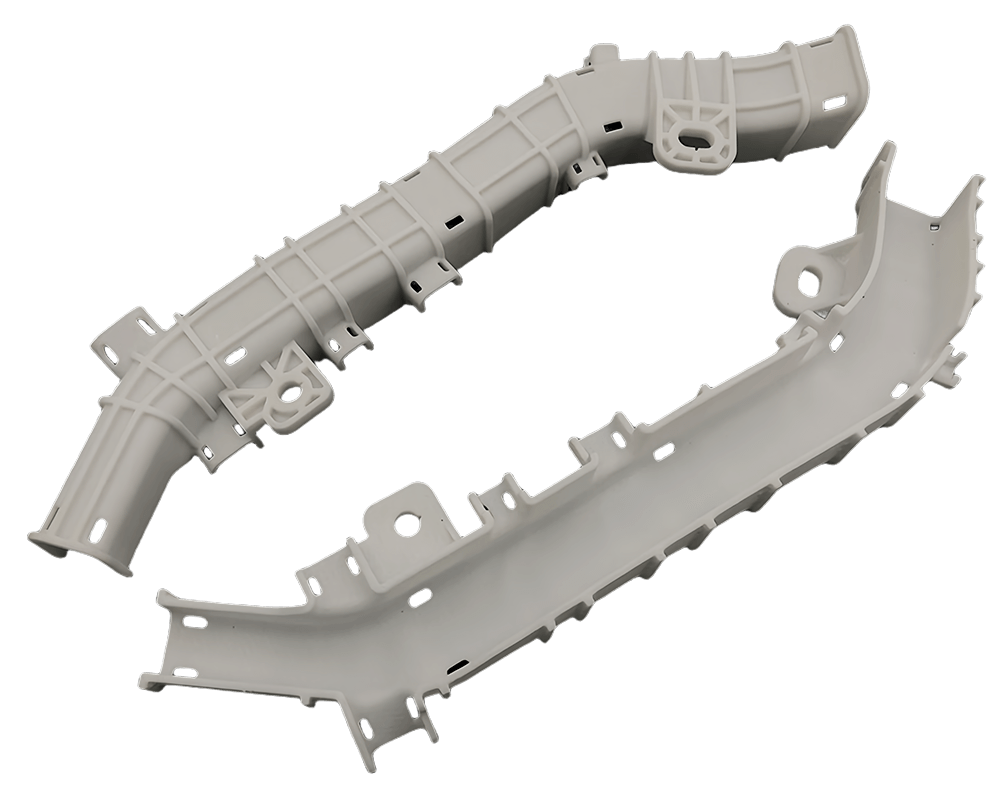

Automotive cable clamps

Requirement: This component will be directly used as a thin-walled part on the assembly line of automobiles, with a wall thickness of only 0.35 millimeters, and must withstand more than 20 90 degree bends.

Solution: Nylon 12 material was used for printing, and the best result broke after 13 bends, which did not meet the requirements. Therefore, nylon 11 material with better toughness is selected.

Result: After using 1100PA material for printing, the number of bends increased exponentially, reaching an astonishing 100000 after testing, fully meeting practical needs.

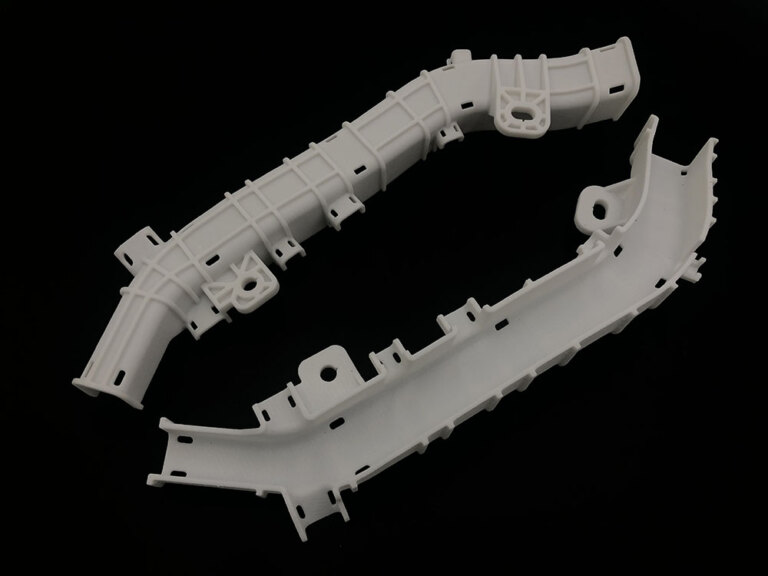

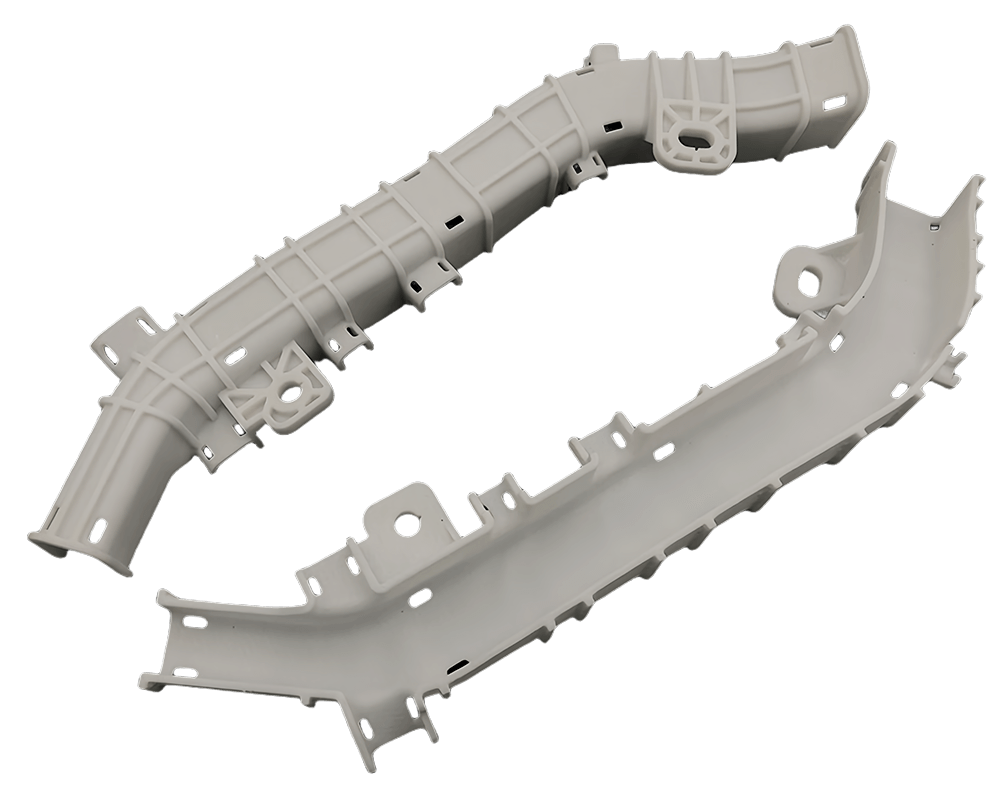

Automotive wire duct

Used for new part development, including prototype design and testing.

Requirement: Quickly respond to the design end (due to its long shape and complex structure, it takes a long time to produce such a complex mold. The design iteration frequency of the parts is high, and conventional production processes are difficult to quickly respond to the design end).

Solution: To meet the requirements of prototype design, nylon 1200F pure material with balanced strength and toughness is selected for printing.

Result: Compared with traditional manufacturing processes, design

Optimization: merging multiple parts into one, while the design can be optimized according to space. The production cost is lower, easier, and faster.

Motorcycle fuel tank and shell components

This is the fuel tank of a newly developed model by the trial production department of a motorcycle company, which is difficult to produce using conventional processing methods. And SLS can be integrated and unsupported, reducing the difficulty of post-processing. The advantage of using SLS production for this item is that it quickly responds to the design end and improves the reliability of later mold making; Saved molding time, cost, and shortened research and development cycle.

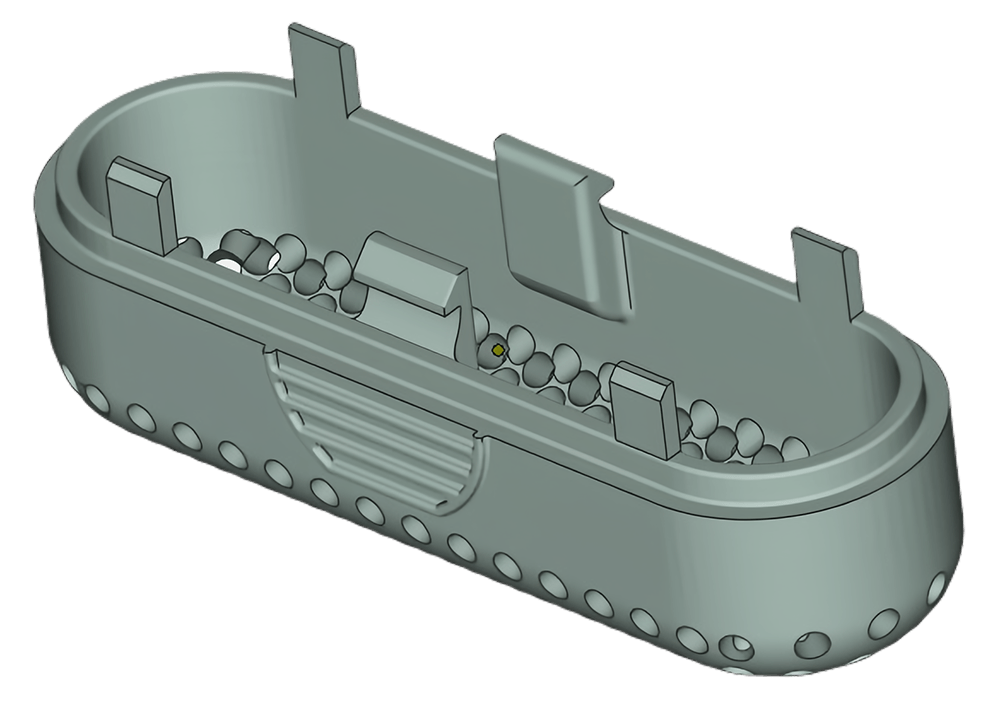

Bottom suction filter of fuel tank

Requirement: Used to reduce the risk of foreign objects or contamination in the fuel tank to protect the outlet of the fuel tank. When in use, the component is inverted at the oil outlet, so it requires strong toughness and oil resistance.

Solution: Nylon 12 components are prone to breakage during assembly due to poor resistance to disassembly and assembly, so nylon 11 material with better toughness is selected.

Result: Meeting the requirements for trial assembly and testing, the first batch has been delivered.