Home appliance industry

Accelerating product innovation research and production through additive manufacturing

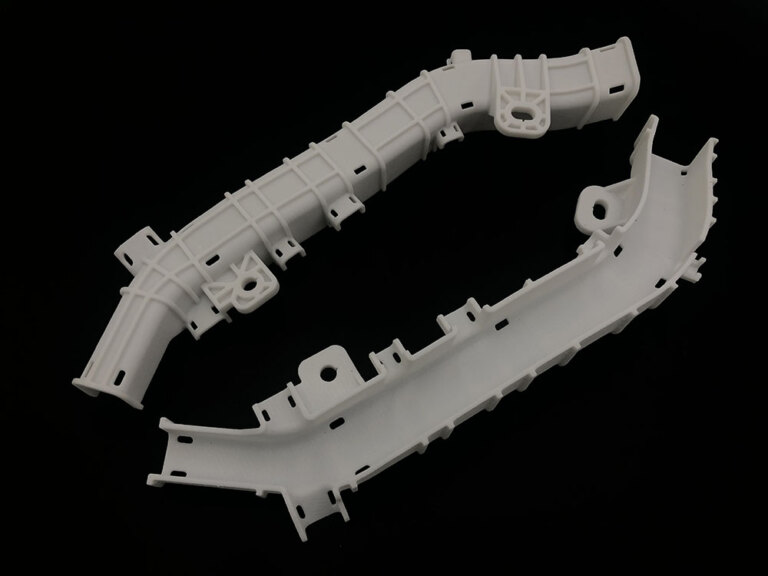

The emergence of 3D printing technology provides a very good application tool for product innovation and research and development in Chinese home appliance enterprises. Using 3D printing can greatly shorten the research and development cycle, while reducing the production time and cost of shell and internal structural models. In this way, both the productivity and quantity of new product development in enterprises, as well as the efficiency of R&D teams, have been greatly improved, which can enable enterprises to gain leading advantages in time, space, and market.

The advantages of 3D printing

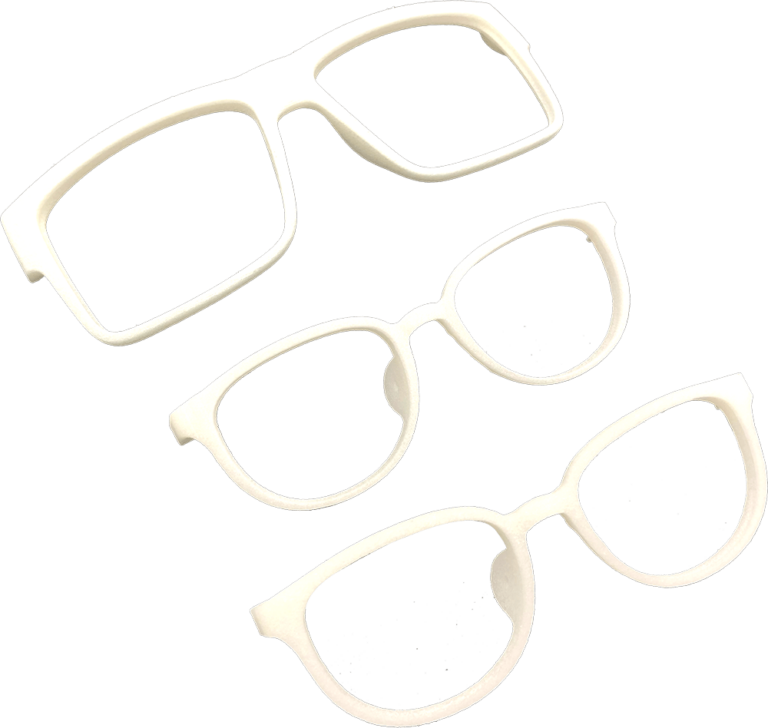

We offer SLS 3D printing services aimed at overcoming complex geometric shapes and producing lightweight components.

Accelerate prototype manufacturing and product development for producing automotive parts

- Lightweight structure

- Hollow structure

- Integrated structure implementation

- Design innovation

Lower cost

- SLS 3D Printing Helps with Low Cost, Small Batch Production

- Can quickly complete the process from prototype design to production manufacturing, reducing costs by 70%

Shorten production cycle

Accelerate prototype manufacturing and product development for producing parts

- On demand production

- Lower production cost

Xianfeng's Manufacturing Capability in the Home Appliance Industry

- Electrical box

- Switch box

- Household appliance casing

- Central electrical board

- Circuit breaker

- Insulation cover

- Wire wrapping skeleton

- Coil skeleton

- Rotor

- Retaining ring

- Dishwasher door gasket

- Drying machine ventilation pipe

- Washing machine frame and hood

- Refrigerator door gasket

Case Presentation

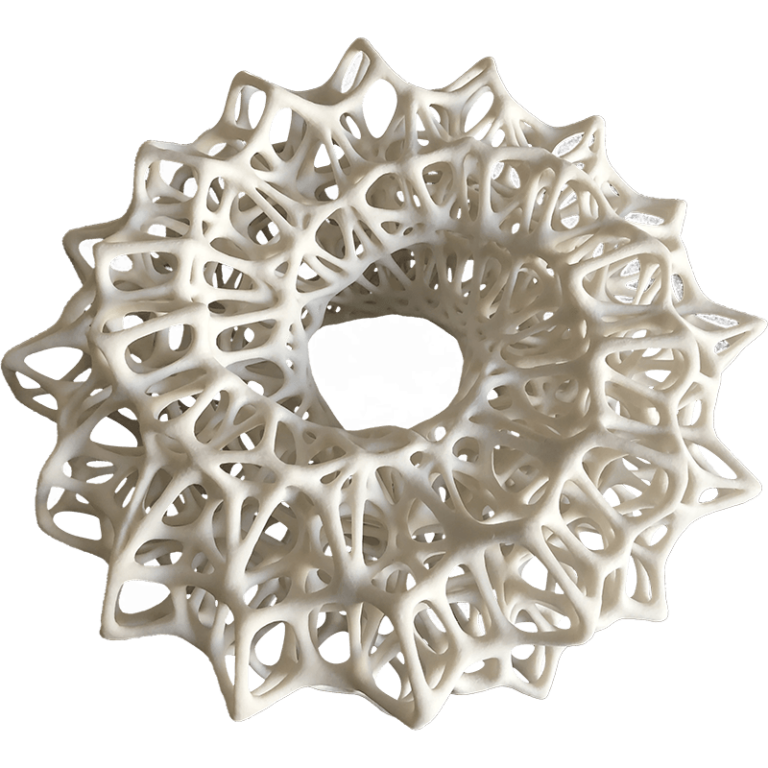

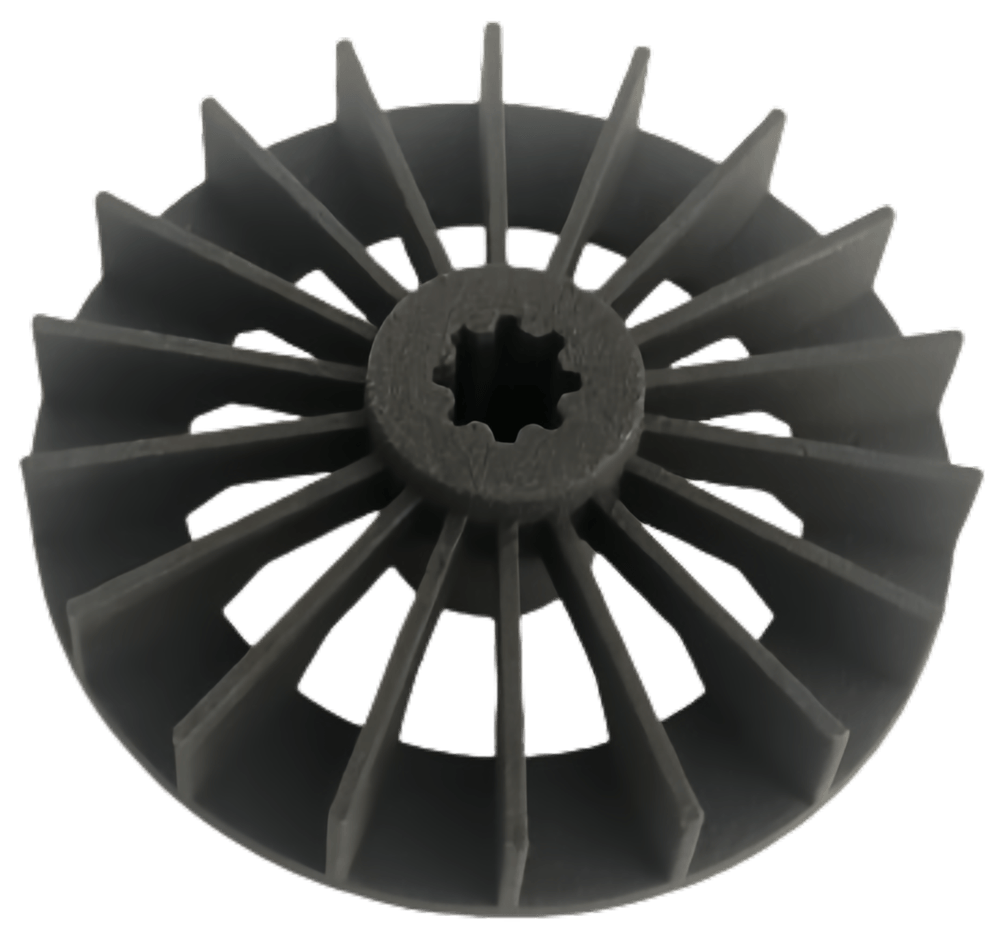

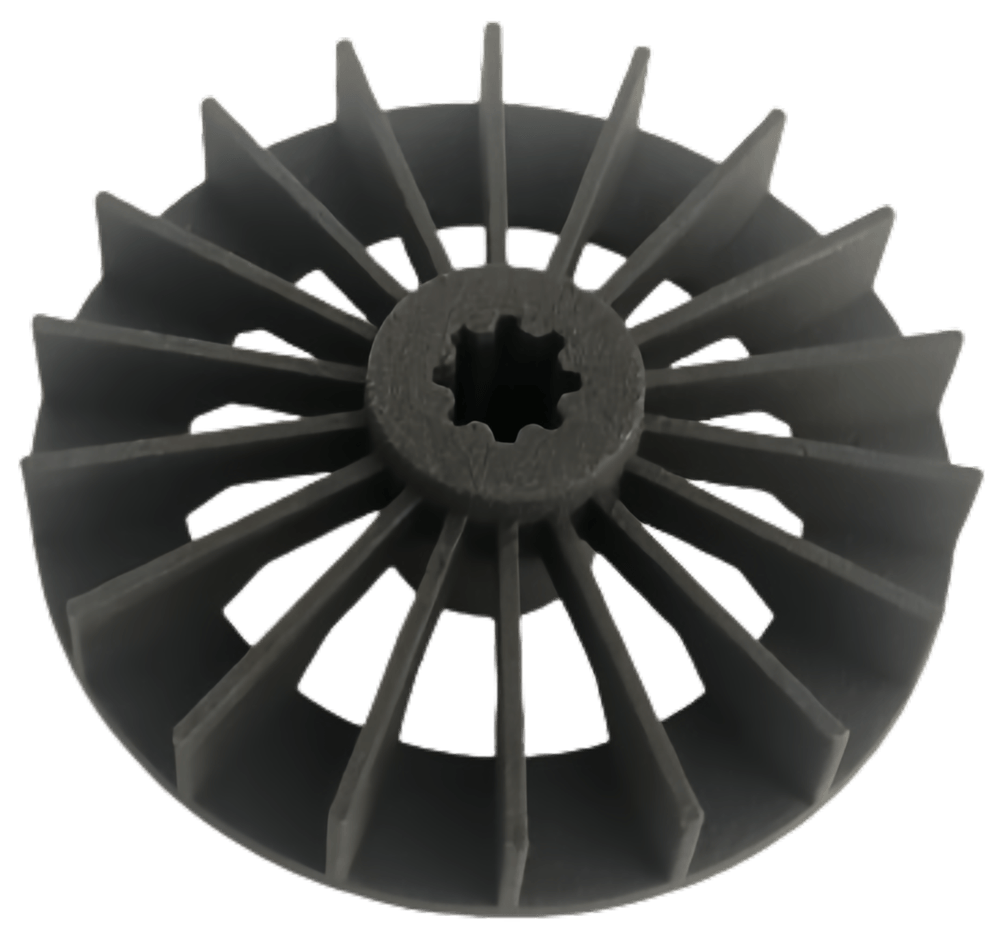

Hair dryer fan

Requirement: Verify the rationality of the fan flow field and the feasibility of the material used

Solution: Select 1200F materials with similar performance according to the strength and temperature resistance requirements of the design parameters,

And improve the fan structure

Result: Accumulated a large amount of data for the improvement and development of fan molds, and significantly improved them

Saved time and costs.