Consumer goods industry

Bring your innovative designs to market faster through on-demand manufacturing

The consumer goods industry is developing at an unprecedented pace, and the demand for personalized design is higher than ever before. Polymer 3D printing provides numerous advantages for manufacturers and consumers. Customization dominates by allowing consumers to design their dream products, whether it’s unique home items or personalized fashion items.

At the same time, polymers also address the key challenge of mass producing aesthetically pleasing and personalized products in the industry, as they can create eye-catching artistic designs. In terms of production, 3D printing provides manufacturers with flexibility to quickly adapt to constantly changing needs and customize parts or production variants at lower costs.

Polymers can even indirectly contribute to your own sustainable development work and brand. By providing environmentally friendly and waste reducing products, you can attract environmentally conscious consumers and align with ethical market values. Rapid prototyping and iteration are the icing on the cake, as they can accelerate time to market and ensure that consumer products keep up with the latest trends. With the help of polymer 3D printing, the consumer goods market is ushering in a new era of personalization, sustainability, and agility.

The advantages of 3D printing

Personalized customization

We use high-performance materials to enhance the possibility of customized product features.

- Personalized medical customization

- Shoe customization

- Customization of sports equipment

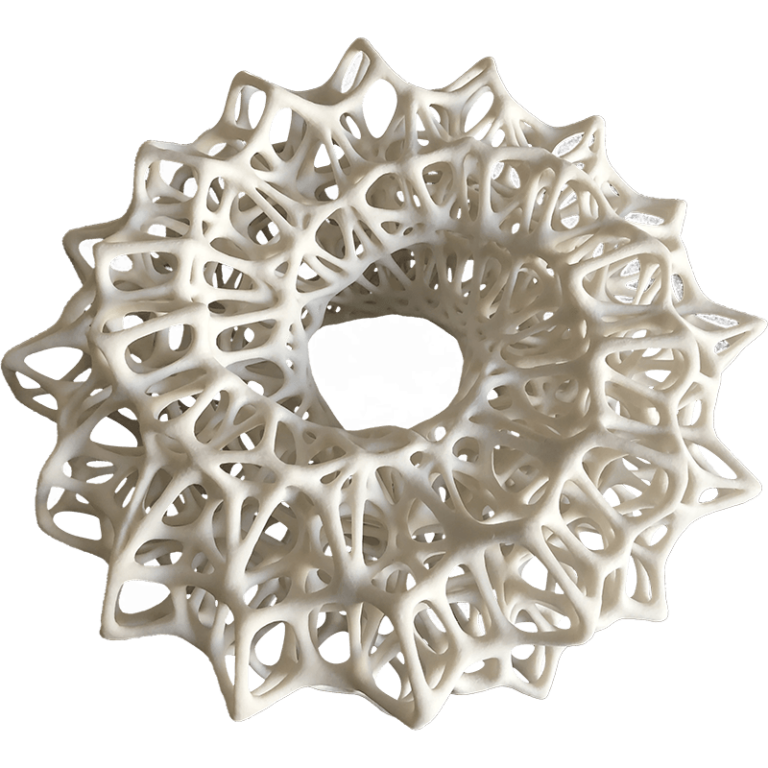

Can manufacture complex structures

We offer SLS 3D printing services aimed at overcoming complex geometric shapes and producing lightweight components.

- Lightweight structure

- Hollow structure

- Integrated structure implementation

- Design innovation

Small batch production

Accelerate prototype manufacturing and product development for producing parts

- On demand production

- Lower production cost

- SLS 3D Printing Helps with Low Cost, Small Batch Production

- Can quickly complete the process from prototype design to production manufacturing, reducing costs by 70%

Xianfeng's manufacturing capability in the consumer goods industry

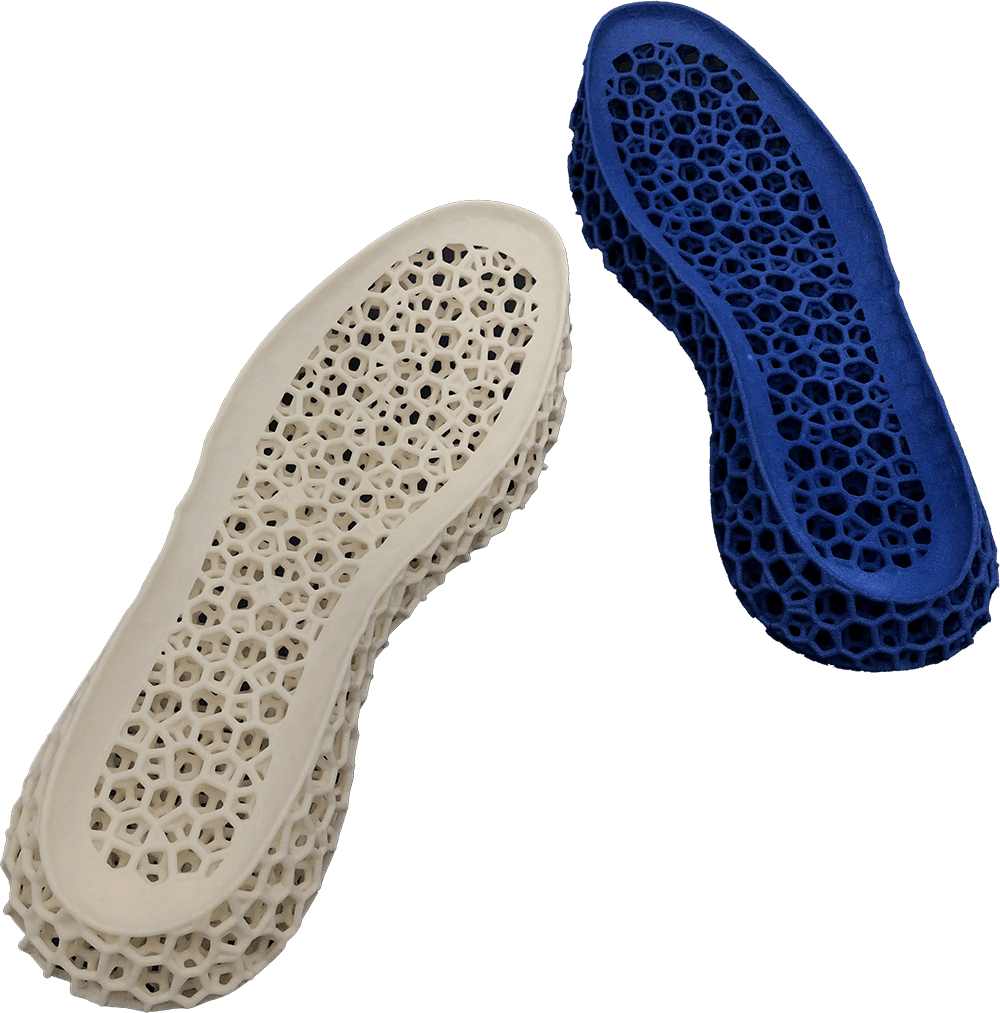

- Midsole of sports shoes

- Mountaineering shoes midsole

- Insole

- Ski boots

- Bicycle seat cushion

- Protective goggles

- Spectacle frame

- UAV

Case Presentation

Shoe midsole

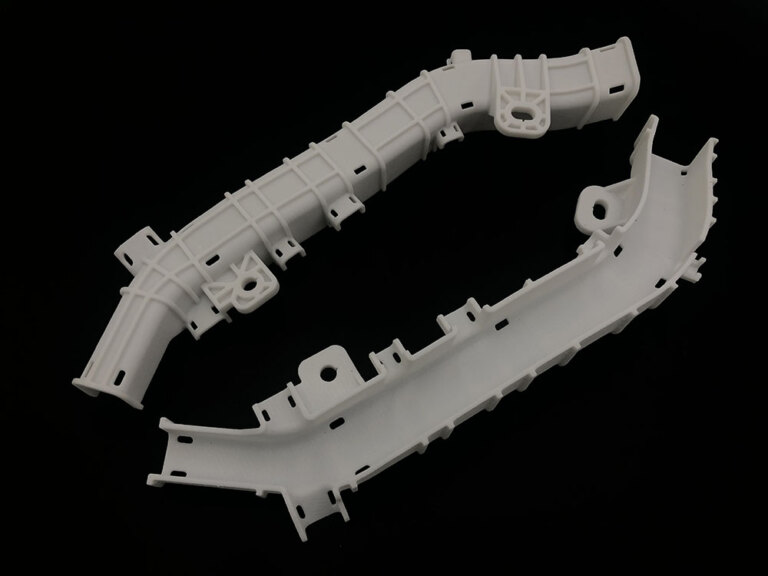

Requirement: Traditional shoe soles are often injection molded, making it difficult to achieve lightweight and customized complex structural design on the corresponding basis.

Solution: Customized honeycomb structure design for shoe soles that better fit the user’s foot shape, using 3D printed elastic materials.

Result: The 3D printed honeycomb structure sole is lightweight, durable, and has excellent cushioning and stability performance. Provide users with a more comfortable wearing experience.

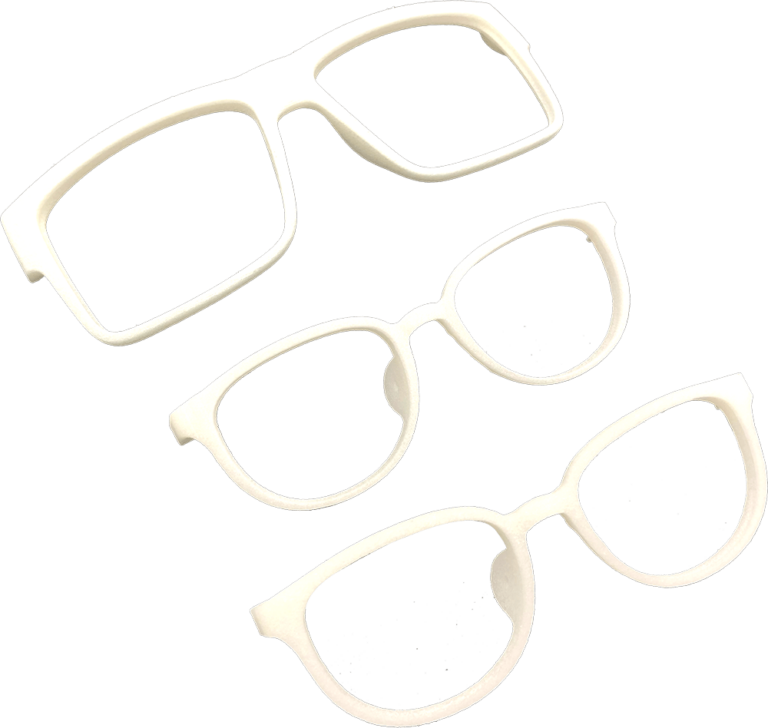

Spectacle frame

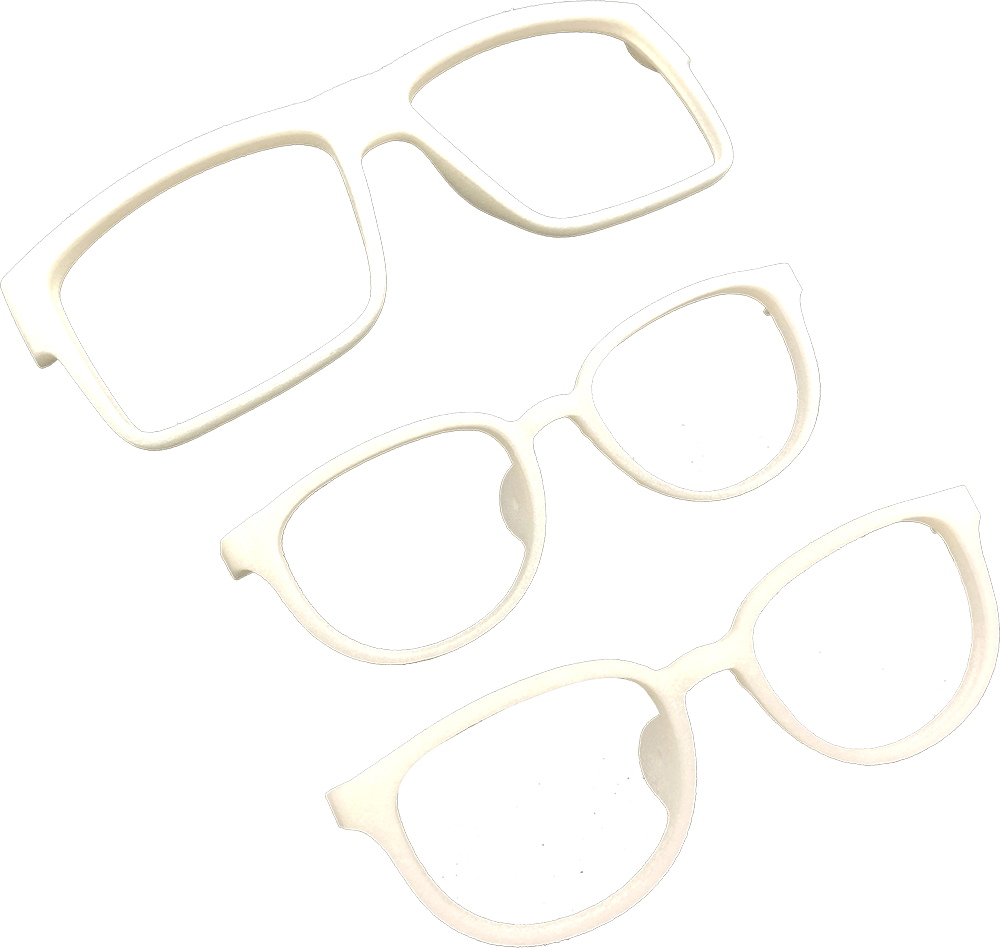

Requirement: Able to have relatively good toughness and consistency under different temperatures and humidities.

Solution: 1100PA has good stress cracking resistance and dynamic fatigue performance. And it has low water absorption, excellent biocompatibility, and good dimensional stability of the product.

Result: It has better resilience and stability than nylon 12 material.