Mechanical industry

Improve part production efficiency through reliable SLS3D printing

The advantages of 3D printing

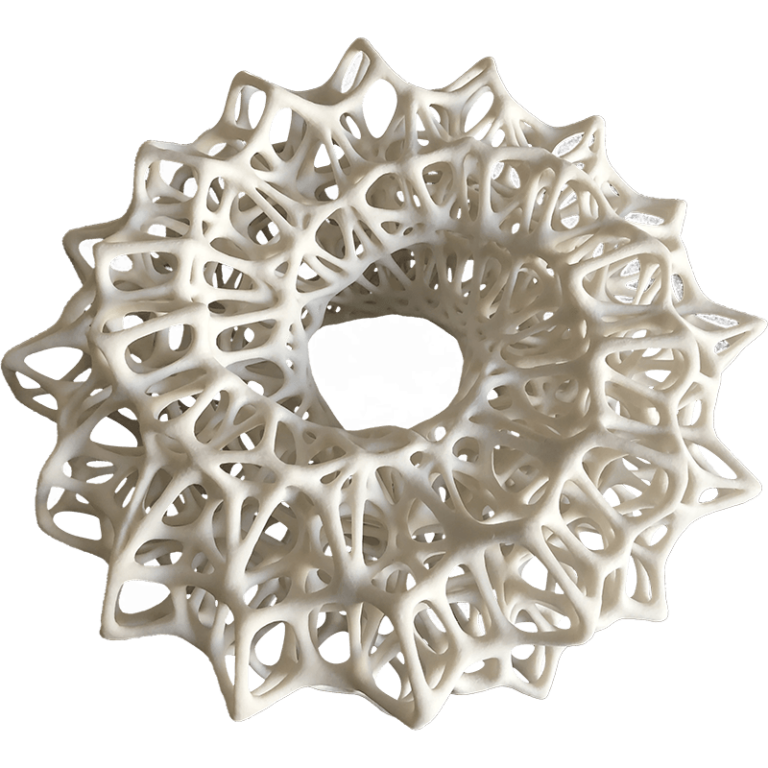

Manufacturing parts with complex structures

We offer SLS 3D printing services aimed at overcoming complex geometric shapes and producing lightweight components.

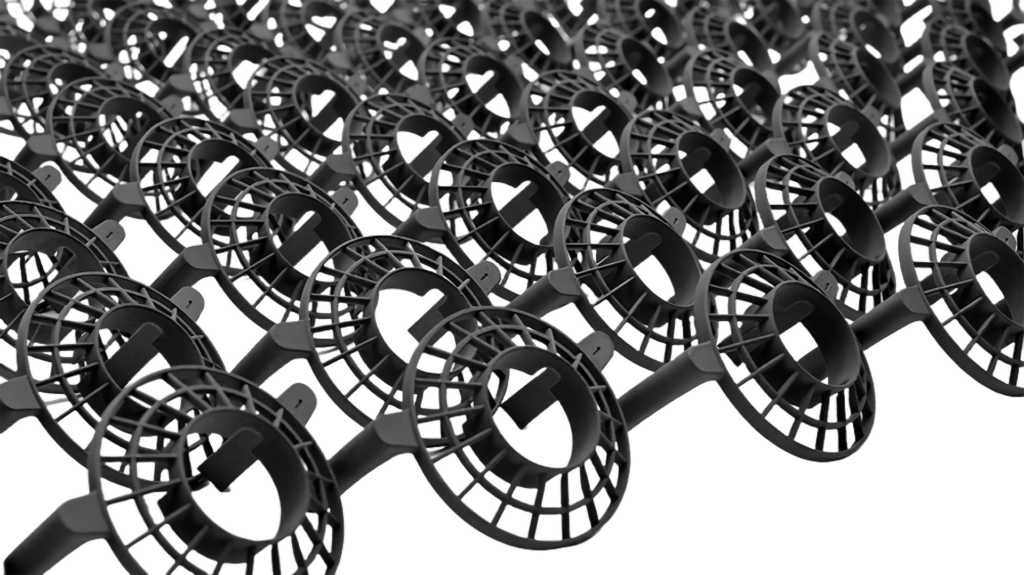

- Lightweight structure

- Hollow structure

- Integrated structure implementation

- Design innovation

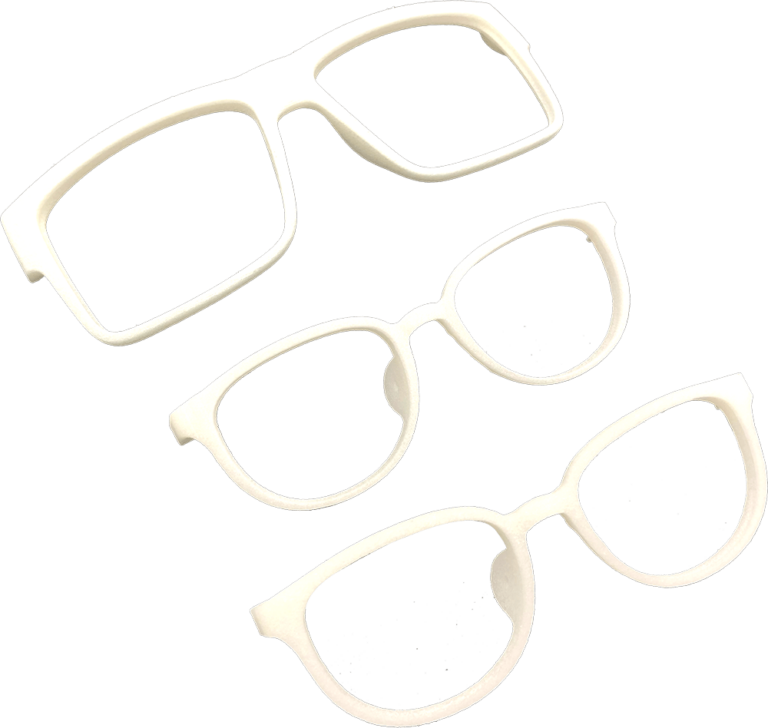

Lower cost

- SLS 3D Printing Helps with Low Cost, Small Batch Production

- Can quickly complete the process from prototype design to production manufacturing, reducing costs by 70%

Shorten production cycle

Accelerate prototype manufacturing and product development for producing parts

- On demand production

- Lower production cost

Xianfeng's Manufacturing Capability in the Machinery Industry

- Manufacturing bearings

- Circular gear

- Cam

- Umbrella gear

- Bearing

- Pump blades

- Customized fixtures

- Sleeve

- Bracket

- Roller

- Pulley

- Pump impeller

- Fan blades

- Propeller

- Oil resistant container

- Shell

- Pulley sleeve

- Bearing cage

- Various rollers

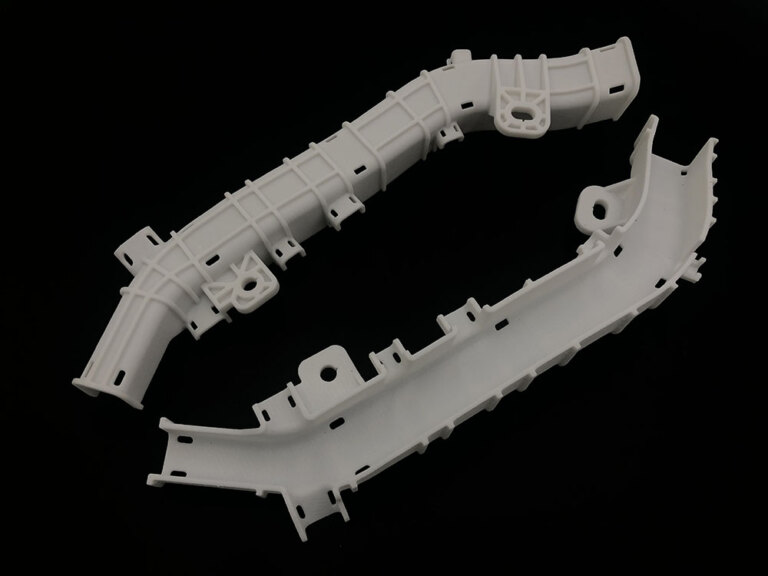

Case Presentation

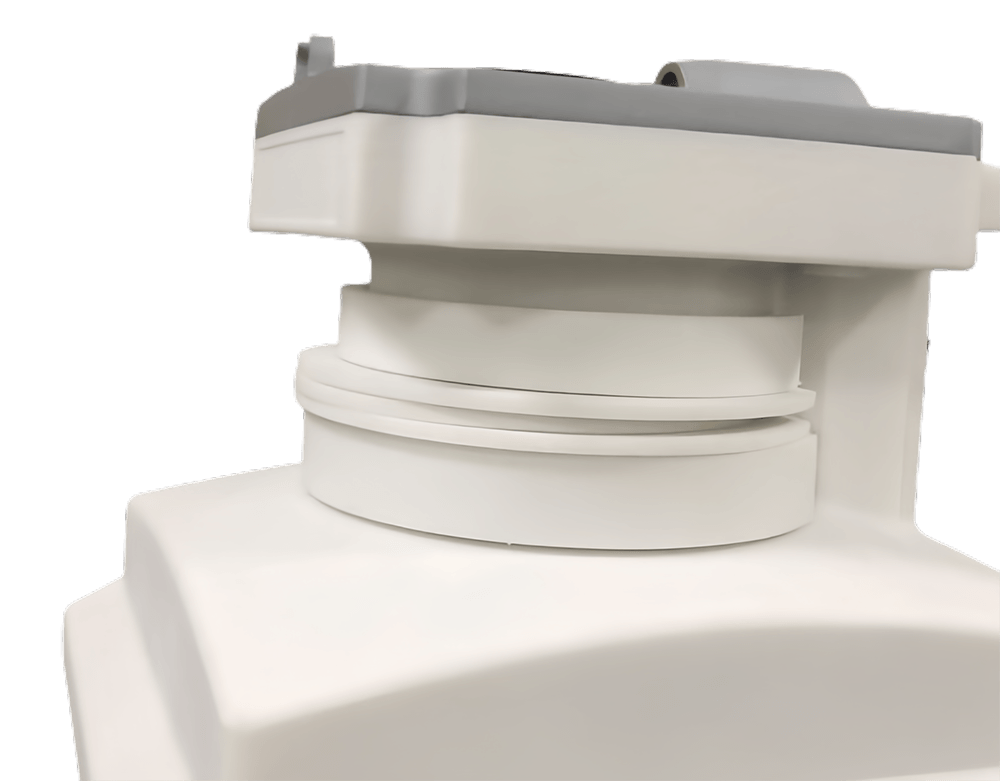

Electrical box group

Requirement: The assembly must have no obvious gaps, aligned holes, and the product must not deform

Solution: As it is a small-scale production, the same batch of powder and equipment will be used

The same cooling time is used to maintain consistency in product performance and size, in order to match each other.

Result: Product consistency is ensured, and almost seamless integration can be achieved.

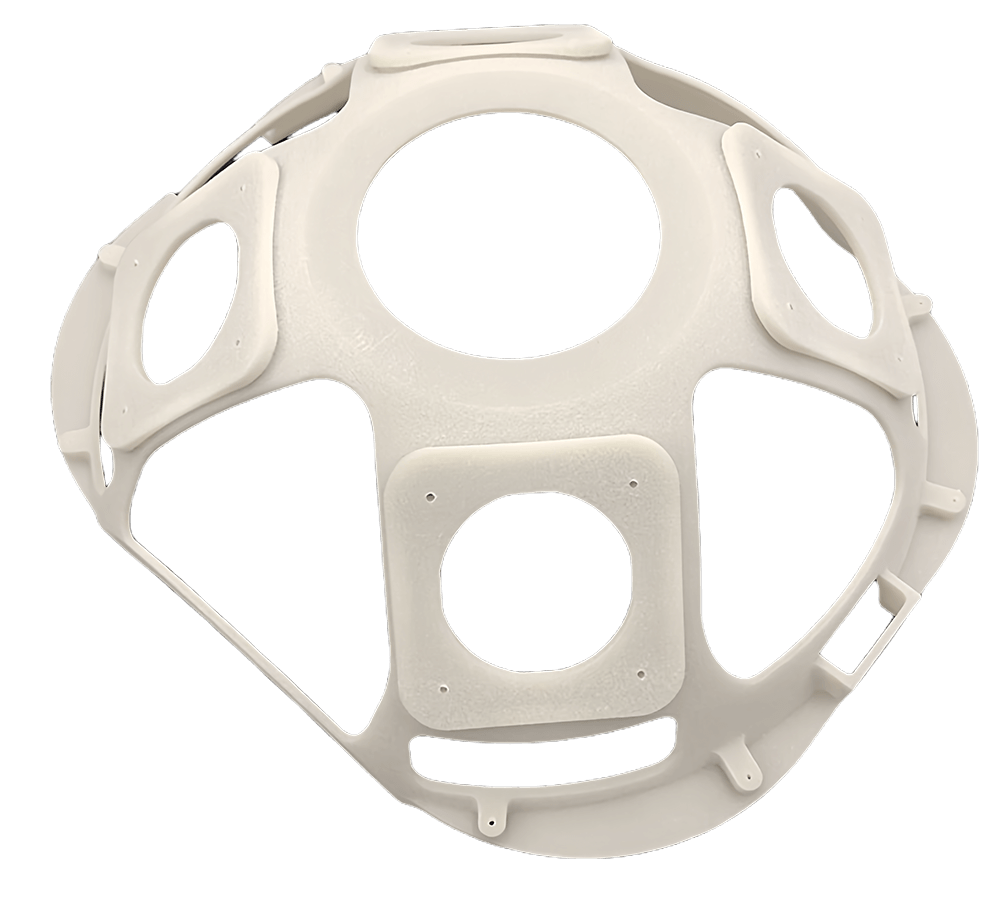

Heat dissipation cover

Requirement: The sample should remain unchanged after the installation of the cooling fan. So it is required that the sample has high strength and good temperature resistance.

Solution: Conventional CNC production is time-consuming, costly, and time-consuming. After trial production, the 1200GF material can meet the needs of long-term work.

Result: 3D printed products not only meet usage requirements, but also save a lot of time in small batch processing. Greatly increased the customer’s production cycle.

Lida hood

Requirement: The outer cover of the mining detection radar is designed for use in harsh environments, and the components must be able to withstand high temperatures of 60 ℃ for a long time while also being shock resistant.

Solution: The customer has previously used FDM technology for nylon 12 material parts, but due to its insufficient impact resistance, most of them will experience direct cracking along the flat surface of the base after about a week of use. Based on the customer’s existing experience, we have selected nylon 11 material sintered parts with relatively better impact resistance and temperature resistance.

Result: After passing the customer’s temperature and impact resistance tests, it has been assembled and used in the mine.