Since its establishment, Xianfeng 3D has been focusing on SLS technology while also emphasizing the research and development of nylon powder to better meet market demand.

The performance of PA12 nylon parts made by SLS laser sintering process is close to that of injection molded ABS, with a density of 0.98 g/CM ³, while the density of injection molded nylon 12 is 1.02 g/CM ³, with not a significant difference.

Many friends habitually refer to SLS as nylon printing, because for a long time, the main printing material for SLS technology was only nylon, and even limited to PA12 material.

With the maturity of technology and the entry of more material manufacturers, there are now many materials that Xianfeng 3D can stably print. For example, there are PA12, PA11, PA6, PP, as well as PEBAX and TPU elastomers.

1.Introduction and Application of PA12 Material

The full name of PA is Polyamide, scientific name is Polyamide, commonly known as Nylon.

Nylon is the top of the five engineering plastics. In terms of molecular structure, it is a long-chain polymer composed of repeated amide groups (- CO-NH -), and has good mechanical properties, wear resistance, self-lubricating properties, and chemical stability.

The chemical name of PA12 is polydodecylamine, which is the most widely used long carbon chain nylon.

PA12 is resistant to seawater immersion, has good toughness, alkali resistance, good mechanical and electrical properties, low water absorption, high dimensional stability, and is easy to process.

Multiple applications:

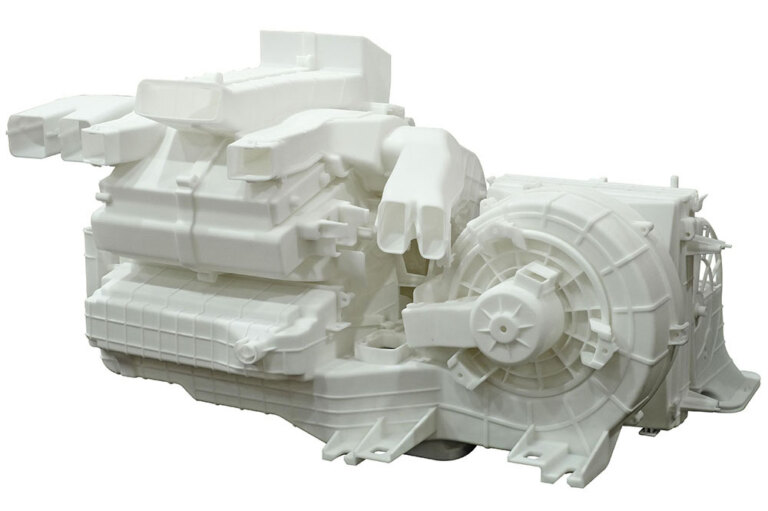

- In the automotive field: headlight housings, instrument panels, intake grilles, etc

- Medical field: surgical guides, rehabilitation protective equipment, etc

- Aviation field: door handles, control levers, antenna covers, etc

- Electrical field: electrical boxes, coil frames, rotors, etc

- Industrial field: bearings, pump blades, customized fixtures, etc

2.Research and development of PA12 material

The XF1200 series material is Nylon 12 ultrafine spherical powder material independently developed by Xianfeng 3D.

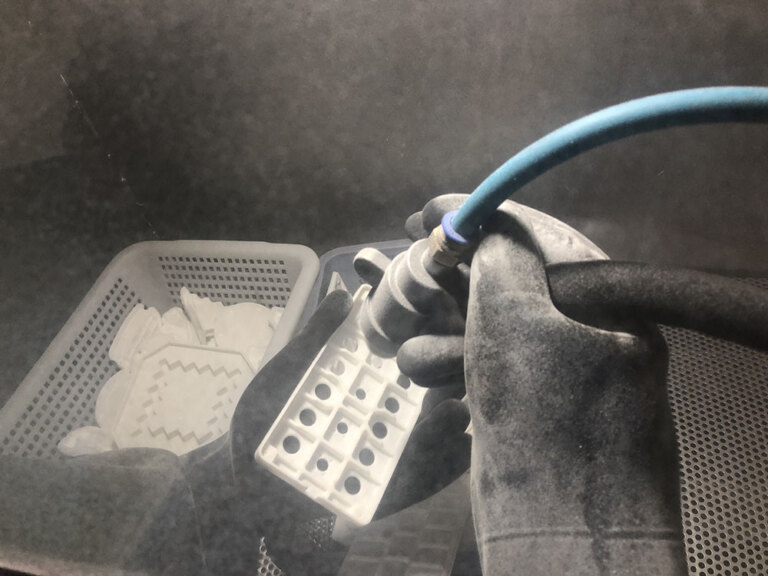

Material characteristics: stable performance, smooth surface of parts, high composite utilization rate, low cost

Application areas: military aerospace, automotive, white goods, prototype models

Reason for selection: small batch, personalized, complex structure, short delivery time

Product purpose: Verify design, parts application

Compatible devices: German EOS, Huashu High Tech

1)XF1200GF

Advantages: Good rigidity, heat resistance, stable molding process, and good dimensional stability

Usage: Can replace CNC and injection molded parts, especially suitable for applications such as prototype, automotive, and power tool casings

2)XF1200PA

Advantages: Good toughness, corrosion resistance, stable molding process, and good dimensional stability

Usage: Aerospace, medical, household appliances