Introduction:

Changzhou Xianfeng 3D Technology Co., Ltd. is a high-tech enterprise specializing in laser rapid prototyping (industrial grade 3D printing). Main business: Production of polymer powders for 3D printing, product design, 3D printing rapid prototyping processing services, and corresponding post-processing. We are committed to providing high-quality service platforms for Made in China, Created in China, and Industrial Upgrading, and offering customers professional one-stop high-quality solutions for “design and manufacturing” to accurately meet their strong needs.

Text: We warmly welcome Mr. Olivier POYET, General Manager of Akoma Nylon Business Unit in France, and General Manager of Powder and Raw Materials in the Asia Pacific region to visit Xianfeng 3D for guidance and to discuss cooperation.

On April 21st, Mr. Olivier POYET, General Manager of Akoma Nylon Business Unit in France, and General Manager of Powder and Raw Materials in the Asia Pacific region visited our company for on-site inspection and negotiation of cooperation. The relevant leaders of the company warmly received and had cordial talks.

In order to provide partners with a more comprehensive understanding of the company and deepen cooperation, the company leaders accompanied the group to visit the processing workshop.

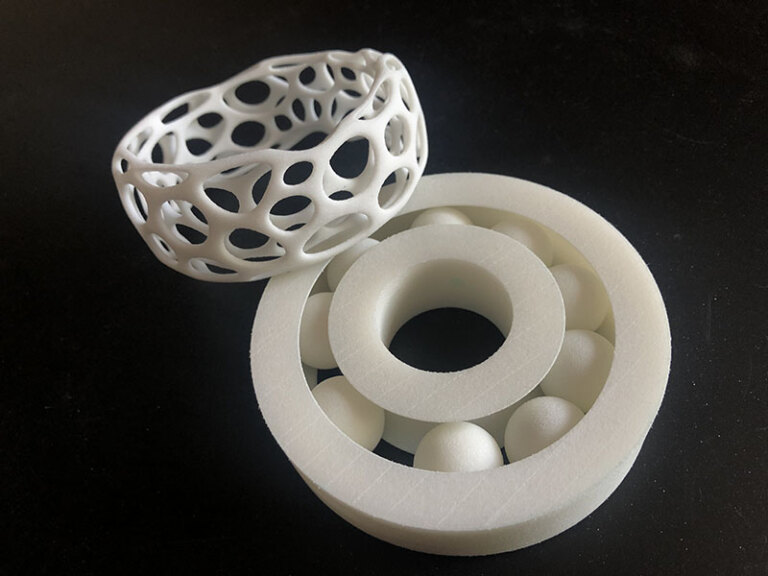

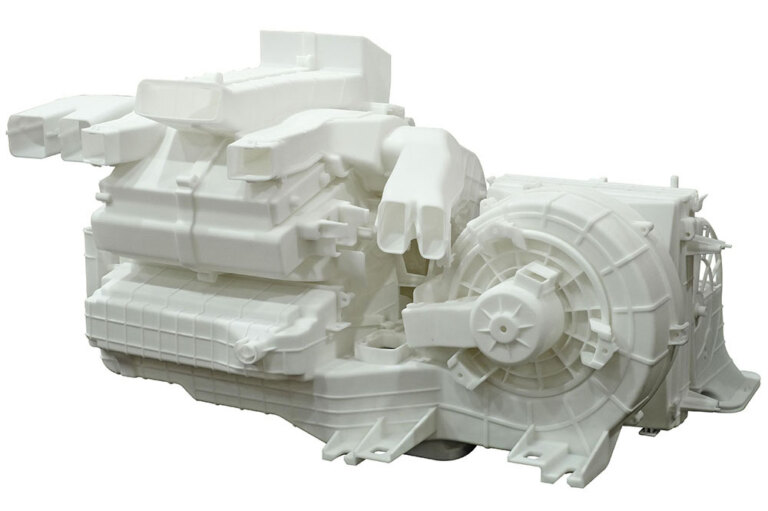

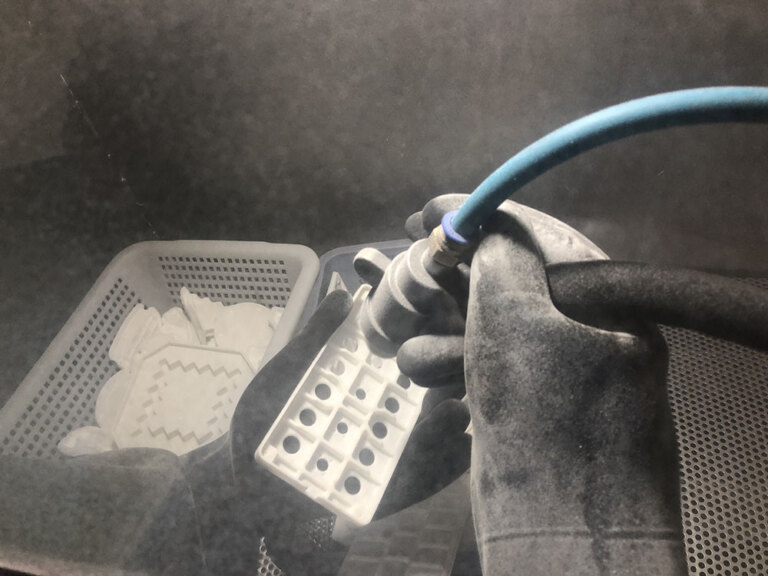

先风三维加工车间及设备

The above are photos of the visit

Under the leadership of company leaders, the group visited the office area, production workshop, and post-processing operation room. The company leaders provided a detailed introduction to the equipment model, SLS molding process, equipment operation flow, and post-processing flow, enabling them to understand 3D printing processing services.

After the visit, in-depth talks were held. At the meeting, the application of PA11 powder sintered by Xianfeng 3D based on SLS laser forming process was showcased, covering almost all fields such as footwear, automotive parts, aerospace and military, medical/medical, etc.

Here are some case studies:

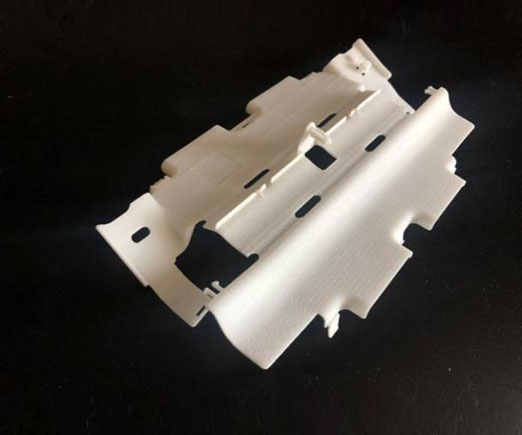

Case 1:

Scenario: Automotive Cable Fixtures

Requirement: This component will be directly used as a thin-walled part on the assembly line of automobiles, with a wall thickness of only 0.35 millimeters, and must withstand more than 20 90 degree bends.

Solution: Nylon 12 material was used for printing, and the best result broke after 13 bends, which did not meet the requirements. Therefore, nylon 11 material with better toughness is selected.

Result: After using 1100PA material for printing, the number of bends increased exponentially, reaching an astonishing 100000 after testing, fully meeting practical needs.

Case 2:

Scene: Glasses frame

Requirement: Able to have relatively good toughness and consistency under different temperatures and humidities

Solution: 1100PA has good stress cracking resistance and dynamic fatigue performance. And it has low water absorption, excellent biocompatibility, and good dimensional stability of the product.

Result: It has better resilience and stability than nylon 12 material.

Welcome ambitious individuals from all walks of life to visit and exchange ideas.

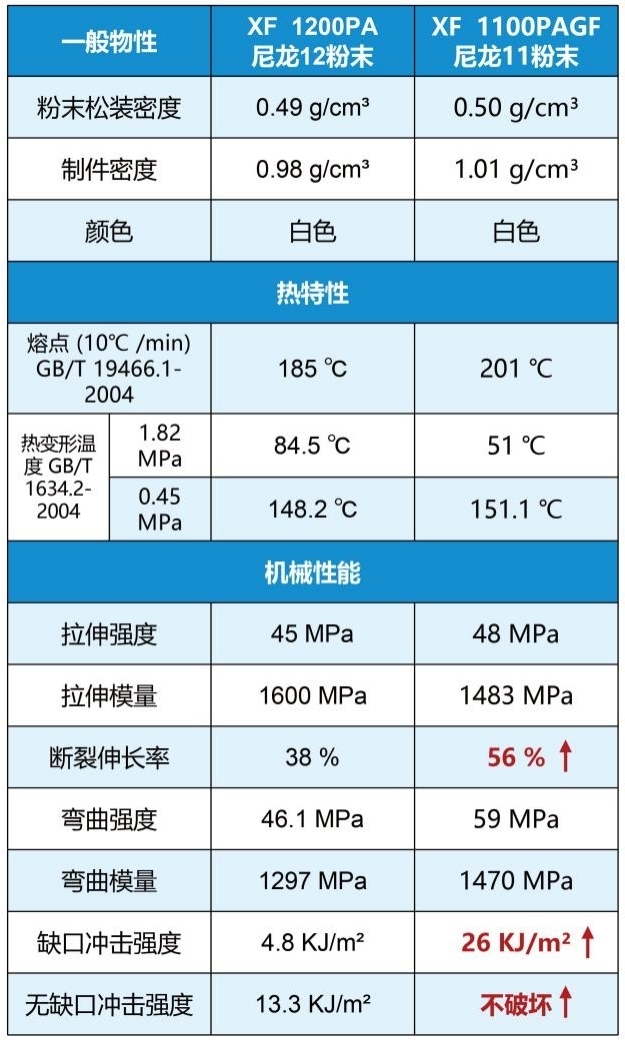

During the meeting, there was a lively exchange on the application of nylon 11 powder in different fields, and high recognition was given to the application of our printed products in end customers. (See the table below for details)

I hope to achieve complementary win-win and common development in future cooperation projects!

Since its establishment, Changzhou Xianfeng 3D Technology Co., Ltd. has always adhered to the service concept of accurately meeting the strong needs of customers. It has a group of professional technical talents who have been engaged in 3D printing rapid prototyping for more than ten years, with comprehensive professional knowledge, good collaboration and communication skills, and can deeply and accurately grasp the product design, development and production requirements of customers. Through scientific and rigorous workflow, combined with long-term practical experience, we provide customers with the highest quality prototype models and batch personalized customized products. We sincerely invite people from all walks of life to visit and exchange ideas.