How does Xianfeng 3D save costs for small-scale production of automotive parts

Key points:

- The use of materials independently developed by Xianfeng 3D can fully meet certain requirements for automotive materials

- Compared with small batch injection molding, the production cost is significantly reduced

- Expanded rapid manufacturing capabilities, utilizing Xianfeng 3D SLS 3D printing technology as a supplementary manufacturing technology for injection molding

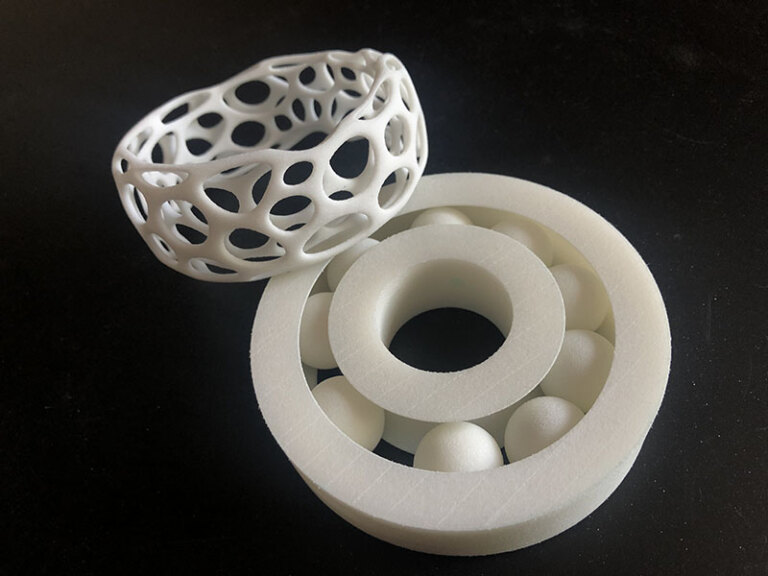

As a 3D printing service provider with decades of experience in the industry, Xianfeng 3D deeply understands the importance of production costs and efficiency in industrial manufacturing applications. With the help of SLS selective laser sintering technology and innovative 3D printing materials, Xianfeng 3D can economically and efficiently produce parts in small batches. Compared with injection molding, it not only saves costs, but also allows them to discover many new market opportunities.

Challenge:

Overcoming the design and production lag of small-scale production in the automotive market

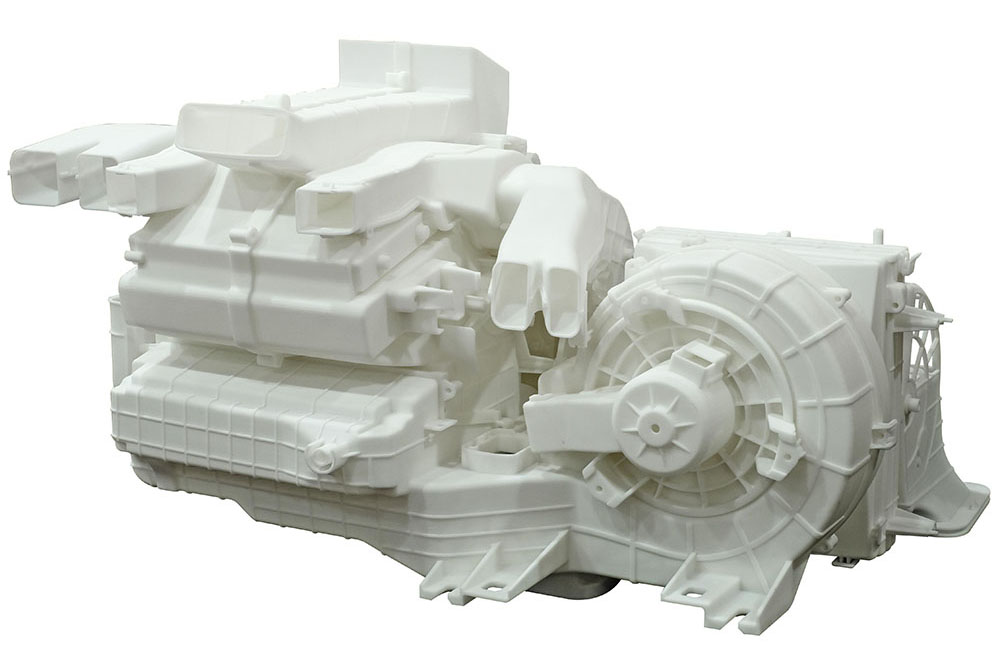

Xianfeng 3D received a small batch production request for a very complex automotive component, and only produces 8000 pieces per year – an extremely low production volume for mainstream automotive parts.

With the gradual popularization of 3D printing technology, orders for small batch production are becoming increasingly frequent, and rapid prototyping, as an economical and efficient manufacturing solution for small batch production, is still a gap. In this situation, it is necessary to respond quickly and competitively to any quantity of production demand.

In order to provide flexible manufacturing solutions, Xianfeng 3D continuously develops and attempts to meet customer requirements in terms of production quality and speed based on existing technological foundations and material equipment.

Solution:

Engineering grade 3D printing materials that meet the requirements of automotive parts

Xianfeng 3D requires a 3D printing material with mechanical and chemical properties comparable to unfilled thermoplastic materials such as nylon or polypropylene.

After repeated experimentation and testing, 7100CF has been proven to be a perfect match for automotive parts requirements due to its strength, toughness, and heat resistance.

Free iteration of automotive parts design for better results

The cost composition of injection molding includes mold design, mold opening, and molding. There are two issues involved here, one is the time cost from design to finalization, and the other is the amortization cost of molds.

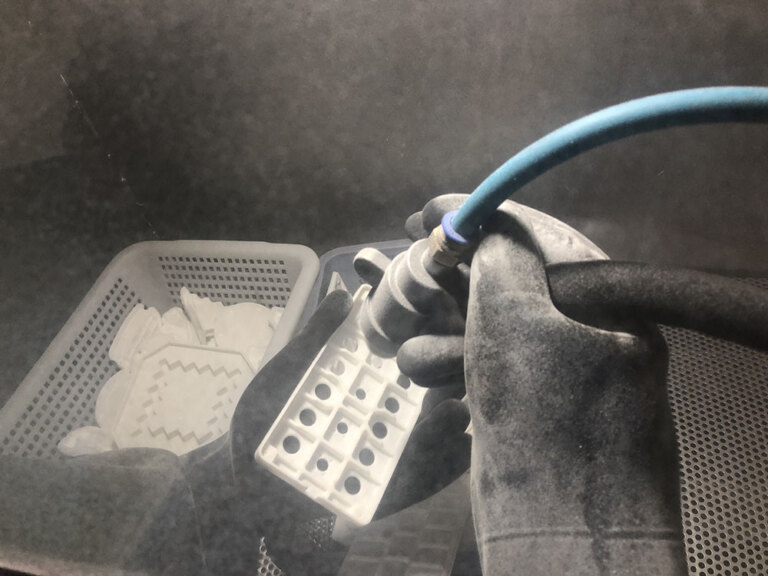

In contrast, Xianfeng 3D has easily and quickly implemented design iterations using SLS technology, and compared to traditional manufacturing methods, additive technology provides greater design freedom.

By continuously debugging the design, Xianfeng 3D optimized the production, research and development, and manufacturing processes, achieving the highest efficiency in terms of printing time and material usage.

Result:

No need for mold injection molding, saving costs and seizing new market opportunities

With the help of SLS selective laser sintering technology and innovative 3D printing materials, Xianfeng 3D can provide customers with parts manufacturing options at a highly competitive price without the need for injection molding investment – significantly reducing production costs compared to injection molding methods.

Overall, Xianfeng 3D has provided confidence for automotive manufacturers to seek new opportunities in the automotive market where traditional suppliers cannot compete through services.

Contact us at www.xianfeng3d.com to learn how Xianfeng 3D can assist you in economically efficient and small-scale production of automotive parts using engineering grade materials.