1.What is SLS?

The full name of SLS is Selective Laser Sintering, also known as “Selective Laser Sintering” in Chinese.

Simply put, selective laser sintering is a powder bed forming process. 3D printing equipment will selectively sinter (rather than melt) particles of polymer powder using laser, and fuse the powdered material layer by layer through heat and pressure until a complete model is built.

2.What is the working principle of Xianfeng 3D SLS 3D printing?

SLS 3D printing uses laser sintering of small particle polymer powder, and the working principle of this process is as follows:

1) Preparation work

- Temperature: The powder area and construction area will be heated to slightly below the melting temperature of the powder.

- Powder spreading: When a layer of powder is preheated to the vicinity of the sintering point, the press roller (Zh á g ǔ n) of the machine will spread the powder that has reached a specific temperature onto the substrate of the construction area or the parts being constructed.

2)Start sintering

- Control the laser beam to sinter the powder layer according to the cross-sectional profile of the part, so as to achieve adhesion between the powder and adjacent formed parts.

- After completing one layer, the construction platform will move down one layer, and the paving roller will lay another layer of evenly dense powder on the construction platform.

- Repeat this process until the entire part is completed.

- The printing is complete, and the entire part is wrapped in unsintered powder.

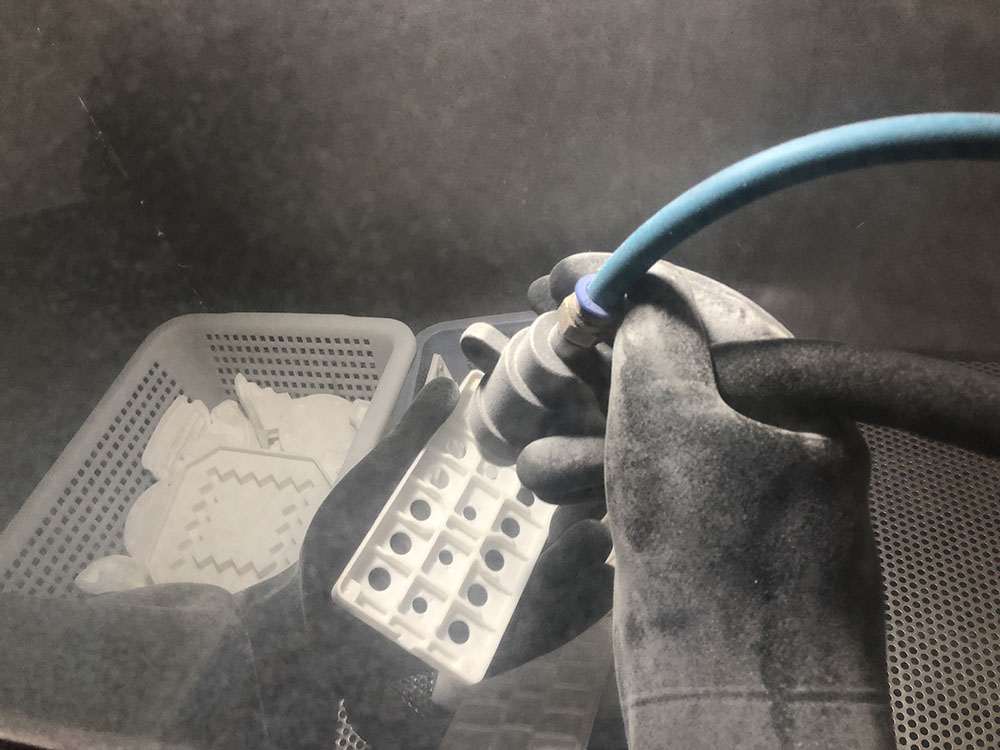

3)Construction completed

- Unpacking: The powder compartment must be cooled before unpacking, which may take a considerable amount of time, sometimes even up to 12 hours.

- Cleaning: Clean parts with compressed air or other sandblasting media

3. Advantages of SLS

1) There are many types of sinterable materials available

In theory, any powder material that can form interatomic bonds after heating can be used as a sintering object for SLS.

2) Widely applicable

Diversified molding materials make SLS technology suitable for various application fields, such as prototype design verification, lightweight design, complex parts, and artistic design.

3) Short part design and manufacturing cycle, fast small batch production cycle

From design to manufacturing, it only takes a few hours to tens of hours, making it particularly suitable for new product development.

4) Integrated molding, high molding accuracy

The overall dimensional tolerance of the workpiece manufactured by this process is:

The test size is less than or equal to 100mm, and the allowable deviation is less than ± 0.1mm;

The allowable deviation for test sizes greater than 100mm is ± 0.1% of the measured size.

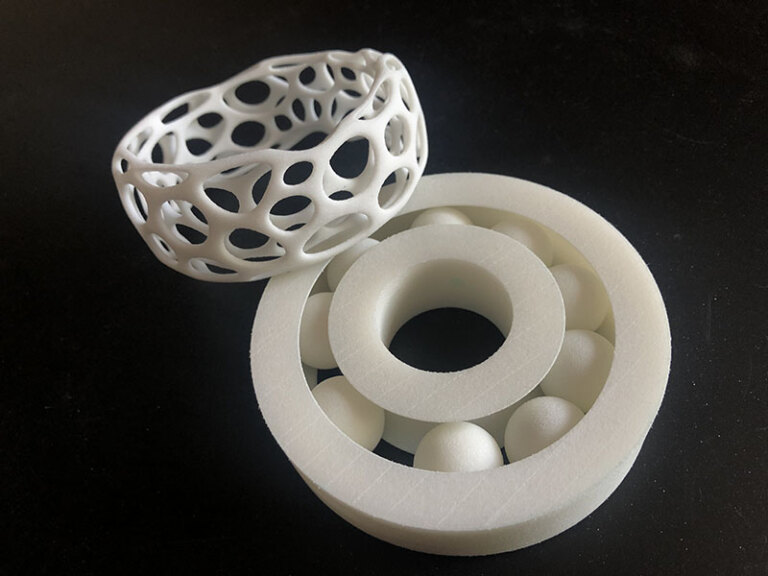

5) Easy molding of complex structures

A key advantage of SLS 3D printing is that it does not require support structures, and the unsintered powder provides all necessary support for the parts.

Therefore, SLS can create complex shapes and structures that were previously difficult or impossible to achieve using other methods, such as hollow structures, hollow structures, etc.

6) High material utilization rate

Unsintered powder can be recycled for use.

Usage scenarios

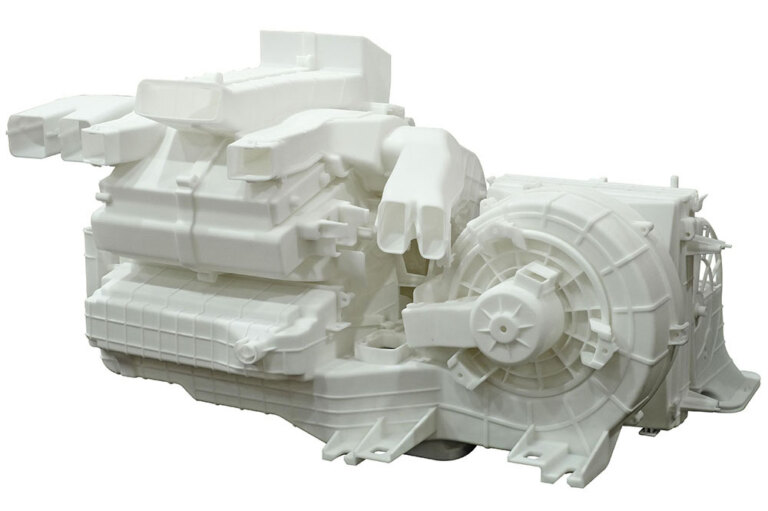

SLS 3D printing technology is now widely used because it is on par with injection molded products in terms of strength and accuracy. This technology is generally applied in the following areas: functional prototypes, spare parts, fixtures and fixtures, design evaluation models, and small to medium batch production.

Compared to injection molding, SLS 3D printing can manufacture parts that injection molding cannot produce, such as parts with internal channels, complex molds, lattice structures, and other geometrically complex features.

Since its establishment, Xianfeng 3D has been focusing on using SLS technology for 3D printing manufacturing. Because it is currently the closest non-metallic 3D printing process to industrial applications, our customers often choose this method for the most complex parts and parts that require extensive customization.

In the 3D printing industry, SLS technology can be applied to many industries, including:

- Automobiles (fixtures and fixtures, prototype cars, racing parts)

- Aerospace (prototypes, tools, ducts)

- Healthcare (prosthetics, braces)

- Consumer electronics products (shell, prototype)

- Military (replacement parts, grip)

- Heavy industry (sand casting, molds)

At present, the development of SLS technology is continuously driven by material manufacturers introducing new materials and equipment manufacturers reducing equipment costs and improving precision and efficiency to further meet different application needs.

At the same time, Xianfeng 3D is constantly developing new materials to meet the increasing demand for higher performance from end customers. In the field of polymer laser sintering processing SLS 3D printing, Xianfeng 3D is undoubtedly professional and trustworthy!

Welcome more partners and Xianfeng 3D to jointly develop more application scenarios!